Agriculture/ 2. Farm Mechanization

Alatoom Mohammad

Lugansk National Agricultural University,

Ukraine

THE CONTINUOUS-RUNNING FODDER MIXER

Constantly

developing food resources (the appearance of new types of premixes, increasing

the range of pelletized feeds, etc.) requires the creation of conditions for

the intensification of the mixing processes.

Continuous

running fodder mixers are most promising, among which mixers with rotating

bunker are of the most practical and scientific interest.

In existing designs

of continuous-running fodder mixers with a rotating bunker a mixing process

occurs in such a way [1, p. 35]. At the circulation motion in the

cross-sectional view of the drum all the material can be divided into rising

(zone ÀÑÂÌ) and rolling down (zone ÀÑÂN) layers (Fig. 1).

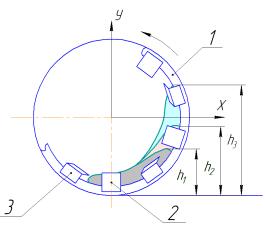

Fig. 1. To the

description of the principle of operation of the existing constructions of continuous running fodder

mixers with a rotating bunker.

A line ABC is a border of the division of

layers. Point C is a circulation

center, around which bulk material is moving about a closed path. On the site

territory ÀÑ the transit of particles

from a rising layer to rolling down layer happens, and on the site territory ÑÂ conversely, from rolling down layer

into the rising one. In the rising layer particles move in concentric circles

with a center on the axis of rotation of the drum and with the angular

velocities equal to the angular velocity of the drum rotation.

Preparation of a

food mixture consisting of three components: (40% - shreddings of rough

feed (hay), 45% - shaving of feeding

root crops, and 15% - milled grain) requires a fundamentally

different approach [2 - 5]. The working tools of the mixer should prevent the

formation of the center of circulation (see point C in Fig. 1), and mixing should occur by an alternate change of the

layers’ position.

This principle

of mixing was taken as a basis of the mixer proposed by us (Fig. 2).

|

à |

á |

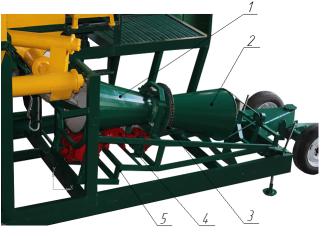

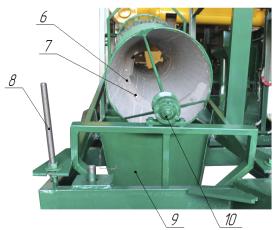

Figure 2. Continuous-running fodder mixer: à – side view;

á – view from the side

of unloading of the final product; 1, 2 – front and back cone, accordingly; 3,

4 – mechanism of the mixer’s drive; 5 – the movable frame; 6 – a screw winding;

7 - L-shaped beaters; 8- mechanism of changing the setting angle of the mixer;

9 – the discharge chute; 10 – the supporting block.

Rotational frequency of the continuous- running mixer is smoothly

regulated with a help of a direct current motor, controlled from a common

control panel through the original transformer regulator. The interval of

variable speed of the mixer is 0-200 min-1.

The mixer works in the following way. The components of the feed mixture (crushed grain, succulent and roughage fodder) are fed into the mixer with a help of proportioning devices. The front

cone 1 with a help of the winding 6, situated on its inner surface, catches components

and sets them moving along a spiral path. The winding is equipped with L-shaped

beaters 7 with a length 100 mm, the beaters are fixed with an interval of 75 mm from one

another. This allows lifting a part of the layer of the

feed mixture at a height, greater than the slope of repose of its components.

This effect prevents the formation of the center of the circulation of the

mixture’s components and mixing is provided by the alternate change of the

layers’ position. Furthermore, the shape of the mixer, consisting of two

truncated cones connected by a smaller base, provides a varying value of the

components’ angular velocity, which also has a positive effect on the

efficiency of the mixing process.

The winding provides two complete rotations of the material. The length of

the each cone is 750 mm. The cones are connected by a cylindrical spacer plate

of the length of 250 mm. The diameter of the larger base of the cones is 500 mm

and of the smaller base is 250 mm. After passing the first cone feeding stuff

is additionally mixed in the symmetrically-situated second cone. The

installation angle of the mixer is changed by a screw mechanism 8 of the

movable frame 5 from 0 to 25 degrees. The design of the mixer allows to change

the quantity and shape of the beaters of the winding, and the scheme of their

installation. The ready feed mixture is unloaded through the chute 9. For the

purpose of improvement of the quality

of mixing the winding of the mixer’s cones is provided not only with L-shaped

beaters but also with rectangular shaped extenders that allows to raise the

layers of the feed mixture at different heights from h1 to h3

(Fig. 3).

|

|

Fig. 3. To the

description of principle of operation of a new design of a continuous –

running fodder mixer with a rotating

bunker: 1 – a screw winding; |

The use of

a continuous-running fodder mixer with a rotating bunker of the proposed design

will allow mixing feed components that differ significantly in

mechanical and technological

properties (moisture content, the dynamic friction coefficient, etc.) effectively.

Literature:

1.

Pershin V.F. Processing of bulky materials in the

drum-type machines / V.F. Pershin, V.G. Odnolko, S.V Pershina. –

Ì.: Mashinostroienie, 2009. – 220 p.

2. Mohammad

Alatoom Improvement of the preparation process of multicomponent fodder for

small cattle / TEKA Commission of motorization and power industry in agriculture and the VOLODYMIR

DAHL and East-Ukrainian national university of Lugansk. Volume XI B. – Lublin,

2011. – p. 213-219.

3.

Zavrazhnov À.I.

Mechanization of preparing and storage of feeding-stuff / À.I. Zavrazhnov, D.I. Nikolaiev. - Ì.: Àgropromizdat, 1990.

4. Alatoom

Mohammad, Diemchenko V.N. Improvement of the process of preparing multicomponent

fodder for small cattle // Scientific reporter of Tavriiskyi state agrotechnological

university [Ålectronic resource]. - Ìelitopol: TDATU, 2011. Issue 1. – Book 3.

- P. 35-42.

5. Àlatoom

Ìîhammad, Braginets N.V., Bakhariev D.N. Requirements to preparing of feeding

stuffs for small cattle // Collection of thesis reports of the international

conference «Modern problems of agricultural mechanics» in memory of the

academician P.M. Vasylenko October 17-18, 2011. Lugansk: ËNAU, 2011. - P. 7-8.

6. Alatoom

Mohammad, Braginets N.V., Bakhariev D.N. Ground of the constructive and technological scheme of the

fodder chopper-mixer for small cattle // Collection of thesis reports of the scientific-practical conference of Lugansk national agricultural

university of January 19-25, 2012.

Lugansk: LNAU, - P. 12-13.

7. Mohammad

Alatoom To the methodology of experimental research of the continuous-running

fodder mixer / TEKA Commission of motorization and power industry in agriculture and the VOLODYMIR

DAHL and East-Ukrainian national university of Lugansk. Volume 12, ¹ 4, 2012. – p. 145-151.