UDC 538.9:621.785.6

Features

the mechanical properties of dispersion-hardening alloy 47HNM by quenching and

aging

Mukazhanov Ye.B.1

Telebayev Ye.Ye.2

Takenova G.D.3

Tynaliev Bauyrzhan4

1 Doctoral

Student, PhD, Associate Professor, Academy of Economics and Law, Zhetysu State

University. I.Zhansugurov, Taldykorgan, Kazakhstan

Taldykorgan

Polytechnic College

2 Taldykorgan

Polytechnic College

3 PhD, Associate Professor, Taldykorgan Polytechnic College

4 Taldykorgan

Polytechnic College

Taldykorgan,

Kazakhstan

Introduction

Austenitic

nickel-chromium alloy 47HNM has high corrosion resistance, low temperature

coefficient, elastic modulus, non-magnetic, low hysteresis and elastic

springback, high fatigue strength and is used in industry, not only as a spring

material [1], but also as an element of the design of nuclear and fusion

reactors [2].

Earlier [3]

discussed in detail the effect of temperature quenching, the holding time for

quenching and cooling rate on the phase-structural state of the alloy 47HNM.

Problem posed

in this paper, was not only in the study of structural phase transitions and

properties of alloy 47HNM, but also to show concrete ways of implementing the

results to improve the process of plasticity and strength characteristics of

the material.

Experiment

The object of

study is the alloy 47HNM industrial manufacturing and standard chemical

composition (47%-Cr, 5%-Mo, rest. - Ni).

Mechanical

testing of samples at room temperature uniaxial tensile carried out on the

installation of the "Glade" by the standard method according to GOST

1497-84. The diagrams were calculated tensile yield strength and durability, as

well as determine the elongation of the samples after the break.

Structural-phase state of the samples was investigated by optical (NEOPHOT-21)

and electron (EM 125K) microscopes. Thin sections for metallographic studies

polished and etched electrolytically in 10% strength acetic chlorine

electrolyte. The samples for electron microscopy in the form of discs were

prepared by jet electropolishing and by thinning of the foils.

Results and Discussion

After

quenching in the temperature range 900-1300 ºC 47HNM alloy structure is

two-phase, consisting of grains of γ-matrix and α-phase particles on

the basis of Cr, which has a bcc lattice (Fig. 1,a). With increasing exposure

time is set for hardening solution hardening α-phase grain growth of the

matrix alloy and increase assorted changes in the nature of the grain

boundaries. Grain growth in the alloy 47HNM very depressed because of the

presence of excess α-phase, which inhibits the migration of boundaries

during recrystallization.

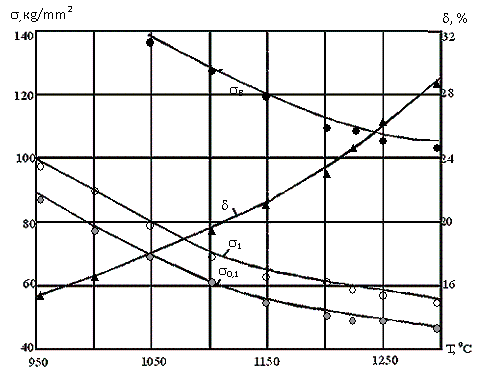

Figure 2

shows the dependence of ductility and resistance to deformation of the alloy

47HNM temperature quenching. It is seen that with increasing temperature

ductility of the alloy hardening increases and the flow stress (σ0, 1 -

yield stress, σ1 - voltage residual strain of 1%, σB - strength) is

monotonically decreasing. Increase in ductility with temperature hardening due

not only to the dissolution, but also the processes of coalescence and

sferoidezatsii excess α-phase.

a b

c d

Figure 1. 47HNM microstructure

of a - hardening of 1250°C, 1 min, x8500,

b - aging at 6000, 10, x6500, c - aging at

700°C, 10h, x8500, d - aging at 1000°C, 1h, x8500

Figure 2 Dependence of ductility and resistance to deformation of the alloy 47HNM

quenching temperature

Analysis of the dependence of the mechanical properties of the holding time at 1300 ° C and 1225 ° C shows that with increasing duration of

heat flow stress drops,

there is a growth of plasticity. Decrease the resistance to deformation,

and increased ductility of the alloy

due to the dissolution of excess α-phase. The process starts with the dissolution of dispersed particles, and with increasing exposure time dissolve and larger particles,

enriching alloying component solid solution matrix. Growth

plasticity with increasing time of homogenization at 1300 ° C occurs up to 30 minutes, inclusive, after which the curve reaches

saturation.

The nature of changes in the mechanical properties as a

function of exposure time at 1250 ° C and 1225

° C subject to the same laws

as at 1300 ° C, but is diminished.

After quenching from 1200 ° C yield strength and

tensile strength of the samples is

higher by more than 10 kg/mm2

over temperature range 1300-1250 ° C. Nature of the change of plasticity at 1200

° C tempering changes

dramatically, the expected growth of plasticity with increasing heating time observed her

fall. The reason for this phenomenon

has not been established, although the nature

of the structural studies of fracture

patterns in cross-section show the presence of the so-called structure of the "slate" kink.

It is considered that the "slate"

of the structure is not a marriage

of heat treatment, but it is possible

that this may be one of the reasons why the ductility and toughness

of the alloy.

Should point to a rather large variations in

the ductility

and strength testing samples quenched from 1200 ° C. Apparently, the spread of values affects

not only the

heterogeneity structure, but also the

partial melting

of the α-phase particles located at the grain

boundaries and the

presence of non-dissolving particles, which

are stress

concentrators. All these factors

lead to the

formation of

micro-cracks, reducing the ductility and toughness of the alloy.

Because, precipitation-hardening alloys used

mainly after

treatment, which includes quenching and

aging, further

interest research the effects of

aging on the structure

and mechanical properties of the alloy 47HNM.

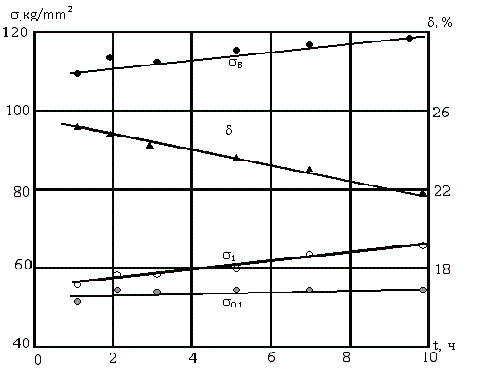

During aging at 600 ° C 47HNM hardened alloy with increasing aging time is a slight

increase in the

strength properties (Fig. 3). Comparing the data of structural studies (Fig. 1b) with the change of the strength properties (Figure 3), we can draw some conclusions, namely the contribution to the strengthening of the alloy, apparently due only to collapse in the excess phase, but as the volume fraction of the phase is small (5-10%), and the amount

of emissions in these particles is from 15 to 40 Å, the increment of hardening is very small. Within the

matrix of any

structural changes

from hardened material occurs (up to 10 hours of age) (Fig. 1, b), and therefore its contribution to

the strengthening of the alloy can be

neglected. A drop of plasticity is likely due to formation

of segregations of alloying

elements on grain

boundaries.

Figure 3: Mechanical properties of

the alloy as a

function of aging

time at 600°C, previously quenched from 1250°C, 2 min.

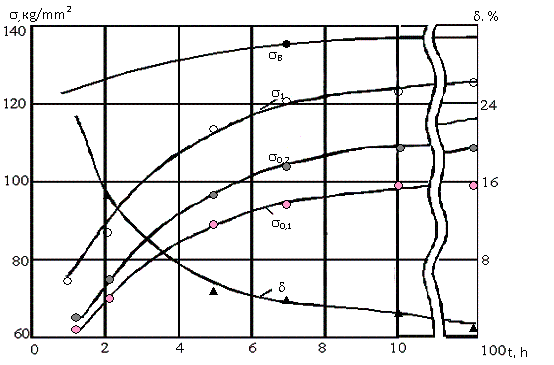

In Fig. 4 shows the kinetics of hardening of the alloy at 700 ° C, pre-tempered at 1250 ° C. In the initial stages of aging is already marked increase in

resistance to small

plastic deformation, the value of

which increases

sharply with

further increase in aging time. The observed increase in hardening stage of

decomposition is

responsible, resulting in rapidly developing intermittent decay, emitting incoherent α-phase (Fig. 1, c).

Electron microscopic study of the

structure and

metallography showed

that intermittent decay starts at the grain

boundaries, and ends after 5-10 hours after the onset of aging (Figure 1, c),

and the volume fraction of the decay is 75-85%, which corresponds to

the maximum hardening. Nature hardening at this

temperature aging is caused by

inhibition of

dislocations, the

separated particles intermittently α-phase.

Ductility of the alloy with increasing aging time decreases

monotonically decreases

to 5% within 10 hours of aging, while for the quenched

alloy was 25%. This decline is

understandable, given the sharp increase

in strength. In

addition, it

should be noted that the

sensors are

working in the

elastic region with a very low residual deformation and therefore such a reserve of plasticity is sufficient for proper function.

Figure

4: The

mechanical properties

of the alloy 47HNM depending on the aging time 700 º C, pre-hardened from 1250 º C, 2 min.

With further increase of the aging

temperature, a change in the behavior of the strength properties of the alloy on the length of aging. In Fig. 4 presents data on the effect of aging time at 800 ° C on the microplastic deformation resistance, deforming stress and ductility of the alloy 47 HNM. First of all, it should be

noted that in

the initial

stages of the flow

stress of aging, especially the yield stress has a value not inferior to the properties of the alloy, aged at 700 ° C. Therefore, this mode is recommended

for the

production of

elastic sensors, as this significantly

reduces the time

of the heat

treatment.

With increasing aging time the yield stress

and other flow stress, including tensile strength decreases, due to the beginning of the

coagulation process in the cells of the intermittent collapse, at 100 hours aging sferoidezatsy slats α-phase. At the same time there is a

growth of

plasticity, ie dislocation that occurred

during deformation, it becomes easier to

overcome obstacles in the idea of large coagulated particles of α-phase. Thus, the

reduction of

strength properties and increased ductility perestarenii alloy caused by the

increase of

distances between

the previously formed precipitates due to their coagulation, reducing the

number of particles

per unit volume of the matrix and decrease the

voltage required to bypass the particles dislocations.

The intensity of coagulation increases with increasing

temperature of

aging, such as at 900 ° C or 1000 ° C, while also there is a

decline of

strength properties. Why spend the final heat treatment - aging in this

temperature range is unreasonable.

Findings

With the increase of the heating time for

hardening flow stress drops, there is a growth of

plasticity, which is

associated with the

dissolution of excess α-phase.

In samples

quenched from 1200 ° C, the

variation of

plasticity changes

dramatically, the

expected growth of plasticity with increasing heating time observed her

fall. It is

assumed that this is

caused by the

presence in the structure of the "slate" kink.

Hardened alloy 47HNM spending below 1225 º C is not

advisable, as it is the deformation leads to the

formation of

micro-cracks, reducing the ductility and toughness of the alloy.

Temperature

increase over

1300 ° C leads to a sharp drop in ductility, melting due to α-phase particles on the basis of Cr and a spreading of the liquid phase at the grain

boundaries.

During aging at

600°C 47HNM hardened alloy with increasing aging time is a slight increase in

the strength properties, due to the collapse in α-phase.

When the aging

temperature of the

alloy to 700 ° C in the initial stages of aging there is an

increase of

resistance to small

plastic deformation, the value of

which increases

sharply with

further increase in aging time. Hardening caused

by intermittent release of α-phase in g-matrix.

At a temperature

of 800 ° C aging time increases the strength

properties of aging are reduced, due to the beginning of the

coagulation process in the cells of the intermittent collapse, at 100 hours aging sferoidezatsiey slats α-phase.

Thus, for high strength with minimal elastic

imperfections heat

treatment of the

alloy must be

conducted in the

temperature range 650-750 º C, and the aging

time must be

between 8 to 20

hours, depending

on the aging

temperature.

Literature

1.

Rahshtadt A.G. Spring steels and alloys. - Moscow,

Metallurgy, 1971 - 496.

2. Solonin M.I., Kondratyev V.P. Votinov S.N. Alloy HNM-1 as a promising material for structural components of nuclear and thermonuclear reactors with water

coolant / / VAST Series Materials and new materials. - 1995. - Issue 1 (52). -P.13-20.

3. Skakov M.K. Mukazhanov E.B., B.K. Akhmetzhanov Phase-structural changes in precipitation-hardening alloys 47HNM after hardening

/ /

Proceedings of the National Academy of Sciences of the Republic of Kazakhstan. Chemical Bulletin - ¹ 2 (356). Almaty, 2006. Pp. 75-78.