Ñåëüñêîå õîçÿéñòâî/4. Òåõíîëîãèè õðàíåíèÿ è

ïåðåðàáîòêè

ñåëüñêîõîçÿéñòâåííîé ïðîäóêöèè

Candidate of technical science

Assankulov Nurlan Arynrashitovich

M.Kh. Dulaty Taraz State

University, 080000, Taraz, Republic of

Kazakhstan

Investigation of drying kinetics of maize in drum dryers

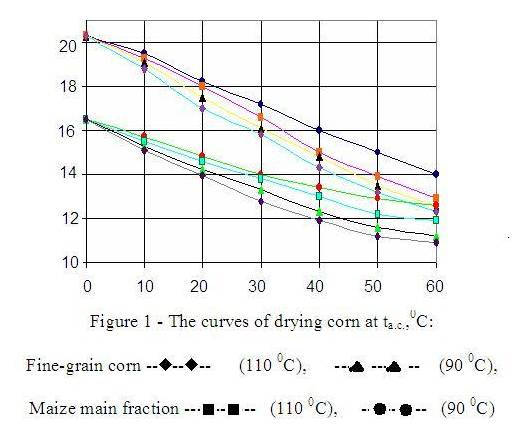

The article provides a

comparative estimate of the rate of drying fine grain corn and grain core

fractions in order to improve the uniformity of drying of maize grain in the

drum dryers. Had studied the kinetics of drying of fine-grained maize varieties

VIR 156 artificial but moistened to 17, 21% based on dry matter (DM) of grain.

The results can be used for practical purposes the duration of convection

drying of maize grain.

The purpose

of work - a comparative estimate of the rate of drying corn and fine grain core

fractions in order to improve the uniformity of drying of maize grain in the

drum dryers.

We studied

the kinetics of drying of fine-grained maize varieties VIR 156 artificially

humidified to 17, 21% based on dry matter (DM) of grain. To compare the rate of

drying corn took the main fraction with a moisture content in respect to the

weight of grain DM 17, 21%. Experiments were performed twice on an

experimental dryer drum set at a

temperature of drying agent 90 and 110 0C (Alpeisov E.A., 1996).

Dried fine grain corn were weighed with an

accuracy of 0,1 g every 5 minutes. Initial grain moisture content was

determined by the ISO 71161985 and then calculated The magnitude of the

moisture WC per MW. Based on these experiments was built drying

curves represent a graphical relationship between WC and drying time

τ (see Figure

1). Drying rate curves obtained graphical differentiation of the curves of

drying.

Figure 1

shows

that

for

fine grain

maize

with increased

WC

as well as

for

corn grain

core

fractions,

characterized by the

presence of

two periods of drying

constant

and

falling

drying rate.

At the

beginning

of the first period there

is a

short warm-up area of

grain, duration of which

is determined by t ac and the

original WC.

Drying rate in the first period is

determined by the equation:

![]()

where N - the

constant drying rate.

In the second period drying rate decreases and

the rate of drying is characterized by K = χN is a generalized coefficient, including the

processes of hydraulic conductivity and water yielding capacity. The proportionality

factor χ is called

the relative ratio of drying.

K-value was determined directly in the second

period of drying curve. The results of determining the values of N, K and χ are given in Table.

Comparative evaluation of drying fine corn and

corn fractions of core show that the rate of drying of fine-grained maize by

20-25% above the rate of drying of corn grain core fractions, which is

explained with respect to the larger surface area of small grains, as well as

differences in biochemical composition and properties.

Table

|

Material type |

ta.c,îÑ |

N, %/h |

K,1/h |

χ, 1/% |

N, %/÷ |

K, 1/h |

χ, 1/% |

|

|

WC =17 |

% |

WC =21 |

% |

|||

|

Fine-grained

corn |

90 |

3,00 |

0,165 |

0,055 |

4,20 |

0,218 |

0,052 |

|

110 |

4,20 |

0,235 |

0,056 |

5,60 |

0,291 |

0,052 |

|

|

Corn

main fraction |

90 |

2,50 |

0,143 |

0,057 |

3,50 |

0,175 |

0,050 |

|

110 |

3,50 |

0,203 |

0,058 |

4,50 |

0,230 |

0,051 |

|

The results can be used for practical purposes

the duration of convection drying of maize grain.

References

1. Alpeisov E.A. (1996)

Intensification of the process of drying and cooling of oilseeds: Dis. Doct.

Tekhn. Science .- St. Petersburg, 429 p.

2. Assankulov N.A. (2007) Intensification of drying

and cooling of wheat grain in the combined unit. Dis. Cand. Tekhn. Science .- Almaty, 156 p.