METHODS OF SPARKS EXPLOSION-SAFE SENSOR

ON THE CDU

Modern production places

high demands on safety equipment

to avoid accidents, explosions, fires. In this regard, increasing

the relevance of the use of spark-explosive sensors that can be used in electric desalting plant

(CDU) in elektrodegidratorah to control the current electrodes.

The deep desalting

of oil reduces corrosion and

sediment reduction in the equipment, increasing the overhaul life

units, improving the quality of raw

material for catalytic processes, as well as commercial products - fuels,

bitumen and coke electrode.

Hence, the need for deep cleaning of oil from

the salt becomes very important. Therefore, the preparation of oil to the processing

performed at the CDU,

which are the basic equipment elektrodegidratory [1].

1 - connection

for input of raw materials,

2 - inferior liquor, 3, 4 - electrodes, 5, 6, 7, 8 - fiber-optic

sensor monitoring the electric current,

9 - Upper liquor, 10 - conclude desalted crude

oil, 11 - bushing; 12 - rootstock Snoy insulator

13 - Settled water

withdrawal

Figure 1 - Cross section of the horizontal elektrodegidratora 1EG160

Fiber sensor

is particularly well suited for this application because it uses a non-conductive connection to the electrode [2].

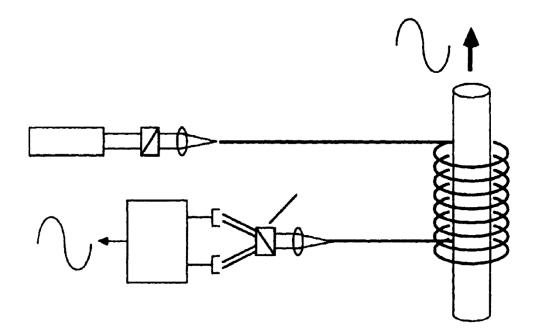

current electrode single-mode fiber Wollaston prism I2 I1 HeNe polarizer

![]()

Figure

2 - Fiber-optic current

display device, based on the Faraday

effect in the high-voltage line

The

radiation of a helium-neon laser is polarized and is introduced into an optical

fiber by odnomodnoe microscope. The fiber is twisted to create a permanent

circular birefringence ατ and N times and wrapped around the tire. The output radiation is

reduced to a parallel beam and prop ¬ admits a Wollaston prism to separate the two orthogonal linearly

polarized modes. The difference in output divided by the sum to give the result

of stability and independence of the intensity fluctuations [3].

To

date, the four principles of management of differentiated fiber-optic current

sensors on the Faraday effect in the CDU:

1)

The principle of open loop.

Lies

in the fact that the required control law is formed only on the basis of

management objectives in accordance with the master control. Management,

implementing this principle is called the running for a given exposure. The

system, built on this principle, is open or not closed. A characteristic

feature of an open system is that the process of working the system does not

depend directly on the result of its impact on the managed object. Hence the

main drawback of an open system - a low accuracy.

2)

the principle or the principle of closed-loop feedback.

Lies

in the fact that the control law is based on the deviation of the controlled

quantity from the master control. Such management is controlled by rejection,

in which the controlled quantity has an effect on the control action. A system

that implements this principle is called a closed system or closed loop

control. The main advantage of closed systems is their high accuracy, but their

performance is lower than in open systems.

3)

the combined principle.

Is

to combine the principles of open and closed loops in a single system. Such a

control that combines the control of the setpoint and the deviation is called

the combined control. It provides high accuracy and high speed.

4)

the principle of adaptation.

Lies

in the fact that systems that implement this principle in the process of

adjusting, adapting to changing external conditions. This is called adaptive

management, and systems operating in accordance with this principle, called the

adaptive and are most advanced. Adaptive systems have in their composition, as

a rule, additional blocks and circuits for the analysis of quality control

process or the external environment, which requires adaptation.

References

1.Pat. Rossii № 62712

kl. G01R29/00 Informacionno-izmeritelnoe ustroistvo kontrolya elektricheskogo toka i magnitnogo polya

2.Tehnologicheskii reglament ustanovki ELOU-AVT-6. S.29-30

3. Urakseev M.A.

Primenenie magnitoopticheskogo elementa Faradeya v informacionno-izmeritelnyh sistemah kontrolya magnitnogo polya i elektricheskogo toka / Urakseev M.A., Levina T.M. // Prikaspiiskii journal: upravlenie i vysokie tehnologii – 2008. - №2 (2). S.24-31.

.