Agriculture 4. Technologies of storage and

processing of agricultural products

Doc. Tech. Sc. V. Yu. Ovsyannikov, Doc.

Tech. Sc. N.N. Lobatchyova, postgraduate student Ya.I. Kondrateva, undergraduate student N.I. Bostynets

Voronezh State University of Engineering

Technologies, Russia

Investigation

of fruit juice concentration in

the freeze

machines

The influence of the initial solids content in the starting apple juice, temperature and rotational speed of the drum on the final solids content of the concentrated product was investigated. [1].

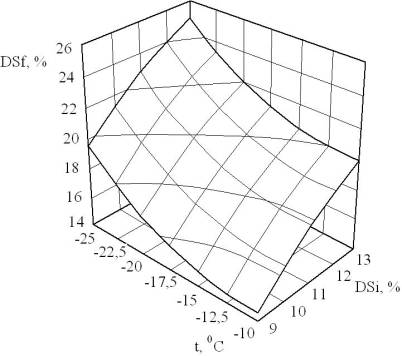

According to the experimental data received we derived dependences of dry solids content in a concentrated product on the drum wall temperature, the frequency of its rotation and the initial solids content in the starting material (Fig. 1-3).

Fig. 1. Dependence

of solids content DSf in the frozen apple juice on the drum wall

temperature t and the initial solids content DSi at drum speed n = 0,08 s-1.

The analysis of the curves obtained

indicated that an increase in the average temperature of the drum wall results

in the monotonous increase of the moisture content in the concentrated product.

Increase of the initial solids content

in the tested juice causes a decrease in the thickness of the ice layer frozen

on the freezing drum surface [2].

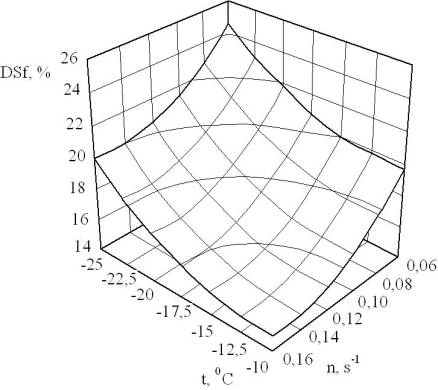

The analysis of the graphs

characterizing dry solids content in the concentrated apple juice depending on the drum rotation speed showed

that this dependence is nonlinear, and dry solids content increases with the

decreasing of the drum rotation speed. Similar curves drawn for apple juice

with increased initial solids content show a significant decrease in the

content of dry solids in the concentrated product.

Fig. 2. Dependence

of the final solids content DSf in the frozen apple juice on the drum wall

temperature t and the frequency of its rotation n with the initial solids

content DSi equal to 11.0 %.

According to the studies, it was

concluded that the greatest impact on the value of the final dry solids content

has the wall temperature of the drum and its rotational speed. Increase in the

drum rotation speed reduces the dry solids content in the concentrated product

as well as increases the product loss carried away by the rotating drum.

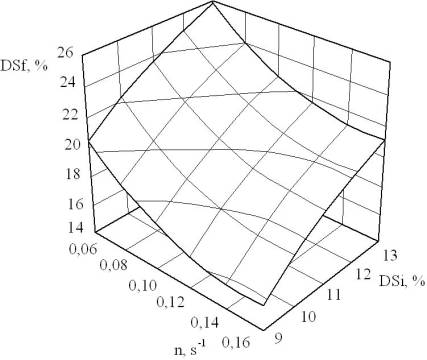

Obtaining of the concentrated apple juice

is possible at an average temperature of the drum wall equal to -22 - 20

°C as well as in the compliance to other rational parameters of freezing

[2]. At the same time the dry solids content in the solution obtained by

melting the ice frozen, lies within a comparable proportion of dry solids

drained with the ice in foreign industrial freezing units.

Fig. 3. Dependence of

the final solids content DSf in the frozen apple juice on the drum

rotational speed n and the initial solids content DSi with

the drum wall t = -20

°C.

The results of the investigations

can be useful in calculating the heat transfer process during the concentration

in drum freezing machines, in the development of technology and

equipment design of the concentrated juices production.

Bibliography list:

1. Sergey T.

Antipov Heat and mass transfer

while concentrating liquid media by freeze drying [Text]/ S.T. Antipov, V.Е. Dobromirov, V.Yu. Ovsyannikov; Voronezh

state technology academy. Voronezh, 2004. – 208 p.

2. Vitaly Yu.Ovsyannikov Determination of the modes of apple

juice freeze drying with the concentration process [Text]/ Agricultural products

storage and processing. № 7. 2012. - P. 16-18.