ИССЛЕДОВАНИЕ ПРИЧИН ДЕГРАДАЦИИ МАТЕРИАЛА ДИСКРЕТНЫХ УСТРОЙСТВ ДЛЯ

ОБЕСПЕЧЕНИЯ ИХ НАДЕЖНОСТИ

Кравченко Ольга Витальевна

старший преподаватель

Черкасский технологический университет

г.Черкассы

RESEARCH THE CAUSES OF

DEGRADATION OF THE MATERIAL DISCRETE DEVICES TO ENSURE THEIR RELIABLE

Olga Kravchenko

senior Lecturer

Cherkasy State

Technological University

АННОТАЦИЯ

В статье дано определение надежности и выполнено классификацию отказов дискретных устройств. Долгий жизненный цикл компьютерных систем должны обеспечивать не только функциональные, программные составляющие, так и физическое аппаратное обеспечение. Одним из условий физического обеспечения является надежность дискретных устройств компьютерных систем.

Проведен анализ физики отказов. Концентрация проникающих в материалы веществ и уровень энергетических воздействий зависят от качества защиты элемента от воздействия внешних и внутренних эксплуатационных факторов. Рост интенсивности их воздействия на элемент увеличивает скорость протекания физико-химических процессов, в результате чего возникают обратимые и необратимые изменения в материалах. Физическая природа отказов базируется на практических задачах по определению надежности дискретных устройств. При этом необходимо учитывать причины отказов и построение корректных математических моделей.

Для анализа уровня надежности информационно-расчетных систем разработаны математические модели по теории надежности. Разработано и описано модель отражающая поведение композитного материала дискретного устройства с учетом завершенных физических процессов в самом материале. При анализе систем типа металл-неметалл, металл-металл существует особая область - тонкий слой, имеющий отличные физико - химические свойства от основных составляющих. Этот слой отвечает за прочность контакта и является связующим звеном между фазами материалов. Численная реализация данных задач проводилась в соответствии с разработанным алгоритмом с помощью существующих математических компьютерных программ с некоторыми дополнениями.

ABSTRACT

The article provides a definition of reliability and failure to classify

discrete devices. Long life cycle of computer systems must ensure not only

functional, software components, and the physical hardware. One of the

conditions is to ensure the physical reliability of discrete devices of

computer systems.

The analysis of the physics of failure was made. The

concentration of penetrating into the material substances and the level of

energy impacts depend on the quality of the protection element from external

and internal operational factors. The growth of intensity of their effect on the flow rate element increases the

physical and chemical processes which occur as a result of reversible and

irreversible changes in the material. The physical nature of failure based on

the practical problem of determining the reliability of discrete devices. It is

necessary to take into account the causes of failures and correct construction of

mathematical models.

For the analysis of the reliability of information and settlement

systems developed mathematical models for reliability theory. Developed and

described the model reflects the behavior of a composite material based on

discrete devices completion of the physical processes in the material itself.

In the analysis of systems such as the metal-nonmetal, metal to metal, there is

a special area - a thin layer having excellent physical - chemical properties

of the main components. This layer is responsible for the strength of the

contact and is the link between material phases. Numerical implementation of

these tasks carried out in accordance with the developed algorithm using

existing mathematical software, with some additions.

Ключевые слова: надежность, деградация, дискретный

устройство, композитный материал, алгоритм, прогнозирование

Keywords: reliability, degradation, discrete

devices, composite, the algorithm prediction

1. Introduction

At the time of computer technology the question of the maximum operation

of computer systems raises. Long life cycle of a computer system should provide

both functional software components and the physical hardware. One of the

conditions is to ensure the physical reliability discrete of devices of

computer systems.

The concept of failure, that is a violation of the discrete device is

the main concept in reliability theory [1 р.25, 2 р.37 ].

The physical nature of failures

is based on the practical problems of determining the reliability of discrete devices. It is necessary to consider

the causes of failures and correct construction of mathematical models [3 р.270]. The discrepancy between the

theoretical model of failures and mathematical model of failures leads to

inconsistency in performance of reliability assessment.

The relevance of this study is that a priori assessment of material

discrete device behavior allows to get reliability of discrete devices of

computer systems at low cost. This in turn will ensure the device manufacturer

of discrete device to guarantee the time of its reliability.

2. The object, goals and objectives of the study

Object of study - materials of discrete devices of computer systems.

The aim of the study is to analyze the causes of circuits degradation

that are made of semiconductors and software reliability of discrete devices of

computer systems.

To achieve this goal it is necessary:

1. to analyze the causes of circuits degradation;

2. to perform classification of methods for assessing reliability;

3. to describe the prediction model of discrete devices reliability.

3. Model of composite

material that reflects the behavior of the material of discrete device

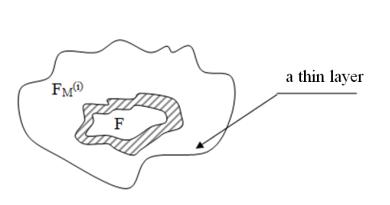

In the analysis of the type ![]() and

and ![]() it was found that in the vicinity of the contact there

is a special region – a thin layer that has different physical - chemical

properties from

it was found that in the vicinity of the contact there

is a special region – a thin layer that has different physical - chemical

properties from ![]() and

and ![]() [4]. This layer is responsible for the strength of contact and is

the link between the phases

[4]. This layer is responsible for the strength of contact and is

the link between the phases ![]() and

and ![]() (Fig. 1).

(Fig. 1).

Figure 1. Model of contact of two bodies in view of the interface

Chemical reactions at the interface cause chemical reaction. It forms a

new phase, which is dissolved during solidification and leads to the fact that

the interface is different in its physical and mechanical characteristics of

the properties of the solid phase F and solidified matrix M.

As a result of the load on discrete components and device temperature

influences on it will have failures in the device due to improper current flow

in the transitions that will cause failure in the work of the devices and

reduce their reliability. Subsequent studies will be devoted entirely to the

mechanical behavior of structural elements of composite materials based on

constructed model of interaction of components.

The problem of prediction of discrete devices reliability is associated

with the problem of creating materials with predetermined properties: strength,

ductility, resistance to high and low temperatures, conductivity, which

requires the creation of composite materials [5]. Composites at successful

technology can withstand high pressure and extreme temperatures. But for the

captured material there is the question of handling different components of a

composite system with different mechanical loads. Therefore, further research

of physical component of discrete devices should be conducted to better predict

the behavior of materials, which will help to avoid some reason degradation.

4. Summary

According

to this goal, we have:

1.

Completed classification bounce discrete devices.

2. The

analysis of the physics of failures.

3. We describe the model of composite materials, reflecting the behavior

of the material of discrete device together with completed physical processes in the material. Crashes in device work due

to improper current flow in ![]() transitions will cause failure in the device and reduce their

reliability; the described model enables to estimate the behavior of the

discrete device material that will continue operation of the device.

transitions will cause failure in the device and reduce their

reliability; the described model enables to estimate the behavior of the

discrete device material that will continue operation of the device.

References:

1.

Gotra

Z.Yu., Nikolaev I.M. (1978) Control of quality and reliability of circuits M .:

Radio and Communications,168p.

2.

Pohrebynskyy

SB, VP Strel'nikov (1988) Design and reliability of computers mykroprotsessornh

. M .: Radio and Communications,167р.

3.

Shore

YB (1962) Statystycheskye analysis methods of quality control and reliability

of [Text]. M .: Sov. Glad.- 552р.

4. Кравченко О. В. Математична модель міжфазової взаємодії в композитах та

уточнення моделі методами обчислювальної математики// Вісник Східноукраїнського

національного університету ім. В. Даля. – Луганськ, 2003. – №7(65). – с.84–88.

5.

Златкін, А. А. Аналіз причин деградації

матеріалів дискретних пристроїв комп’ютерних систем [Текст] / А. А. Златкін, О.

В. Кравченко, О. С. Вовчановський // Технологічний аудит та резерви

виробництва. – 2014. – № 5/3 (19). – С. 37-41.

doi:10.15587/2312-8372.2014.27934