UDK 541.13

SCIENTIFIC RESEARCH CLEANING WASTE

WATER FROM OIL

Iztleuov G.M.-professor,

Zhusabek A.S

SKSU by M.Auezova

Oil

production is a new industry in Kazakhstan that promotes the economy and makes

noticeable social development. This industry has many environmental impacts

such as air pollution, soil pollution and hazards associated with waste

production. Petroleum products are the most common pollutants. A

large number of these impurities contained in the effluent of motor and car

companies, railway companies and agricultural equipment, tank farms, pumping

stations and loading points. Wastewater treatment, there are certain

difficulties associated with the release of these parts of the emulsified oil

and oil products, which form water

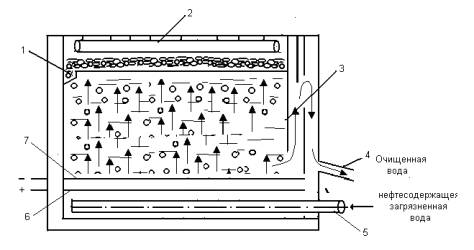

Figure-9. Elektroflotator for cleaning

waste water from oil: 1 pocket charges foam

2- peno device

3- emergents partition

4,5 getting and supply

line, he cathode,6-(titanium),7-an

anode (graphite)

At present, the actual

problem is the development of effective methods of nonchemical intensification

elektroflotatsion cleaning oil and oily water. Positive results were obtained

in the purification of water high effect can be achieved by using a combination

of titanium and graphite electrodes. Concentration of oil in this case

decreases from 350 to 10 mg / l (see Table 1.2)

In Table 1 we studied the effect of current density on the degree of

purification titanium water from oil.

The current density was

varied 25-200 A / m2, and the degree of purification of water has increased

from 69.6% Oil - 89.2%, depending on the salinity of the power consumption of

0.2-1.2 kWh / m3. In Table 2 we studied the effect of electrolysis duration of

the degree of purification of water from oil. Electrolysis time value varied

10-60 minutes while the degree of purification of water from petroleum

increased 89.2% - 99.8%. Use of insoluble electrode-cleaning preferred emulsions, despite this increase

in energy consumption. Increased electrode life, decrease in foam volume and

simplify the technology of its processing compensates for the extra power

consumption. Test installation with such elektroreaktor revealed some features

of cleaning water from oil products. Thus, the cleaning efficiency in floto

depends primarily on the concentration and dispersion of oil particles.

Effect of extraction

increases with their size and quantity without changing the cleaning, the

residual oil wherein the concentration of 1-5 mg / l.

In addition to the electrical parameters, on the degree of extraction of oil

and oil products is greatly affected by hardware design and hydraulic

parameters of the process electroflotation. For example, proposed by "Ford

Motor" elektroflotator countercurrent movement of the water and gas

bubbles, as well as a rotating feed and collection device allows more uniform

distribution of water in the unit volume and to increase cleaning efficiency.

Electroflotation is one of

the most effective ways to purify water from oil and butter, it is carried out

in devices with insoluble or soluble electrodes.

Experiments were carried out special electrochemical cell (Figure 4). Design of

the apparatus for cleaning elektroflotatsion quite simple. The electrodes can

be carried out in the form of plates disposed at the bottom of the unit

horizontally or vertically, occupies almost the entire area of the

bottom to prevent the flow patterns that prevent flotation contaminants

Politkovskaya was found that the efficiency of this method is equivalent to the

treatment of urban wastewater in the aeration tanks to incomplete cleaning,

more efficient and easier to use than biochemical methods of aeration or

biofiltration. When using insoluble electrodes flotation

efficiency depends on the size of recoverable drops. For example, if the

recovery rate of the particle diameter of 18 micrometers is 62.5%, the diameter

of 10 micron - 23.3%. Particle diameter of 5 m oil electroflotation almost

recovered, and a diameter greater than 22 microns are removed effectively

Physical and

chemical processes taking place in the water purification devices

elektroflotatsion include electrolytic generation of gas bubbles, the adhesion

of gas bubbles and dirt particles, transportation of aggregates formed

"gas bubble - particle pollution" on the surface of the liquid to be

treated.

An important and often determined by the stage of the process is

elektroflotation adhesion of gas bubbles and dirt particles, which occurs at

the molecular level. Approximation vesicle particles is effected by external

hydrodynamic forces, and the distance between them is reduced to 10 ~ 6 mm,

molecular forces start to act. In this case, the act of sticking particles to

the bubble is accompanied by a sharp decrease in the surface energy of the

boundary layers and the emergence of forces that seek to reduce the wetted

surface.

The flotation process flows more successfully than the more general surface of

the gas bubbles and the greater area of contact with them

floatable particles. In systems with the same degree of liquid gas filling the

total surface of the smaller bubbles will be greater and the distance between

the particles and smaller bubbles, which enhances the probability of their

collision.

Electroflotation

method has some significant advantages over other methods of flotation

wastewater: ease of manufacturing devices and the simplicity of their service;

possibility of regulating the degree of cleaning fluid depending on a phase

state of particulate contamination by changing only one parameter (current

density) in the process; high degree of dispersion of the gas bubbles, which

provides the efficiency of attachment of insoluble impurities; no moving parts

in the work area devices, ensuring their reliability and precluding mixing

liquid to be treated and grinding it contains suspended particles; additional

mineralization of organic pollutants with simultaneous disinfection of

wastewater generated due to the anode of the electrolysis products - atomic

oxygen and chlorine.

Table 5

Effect of current density on the degree of purification of titanium water from Oil

|

N |

The current density on titanium À/ì2 |

The duration of the

electrolysis, |

Concentration of oil

in the waste water before purification |

Concentration of oil in the waste water after cleaning |

The degree of purification, |

|

1 |

25 |

10 |

350 |

110 |

69,6 |

|

2 |

50 |

10 |

350 |

82 |

77,6 |

|

3 |

100 |

10 |

350 |

50 |

85,8 |

|

4 |

150 |

10 |

350 |

38 |

89,2 |

|

5 |

200 |

10 |

350 |

38 |

89,2 |

LITERATURE

1. Carter, R.

E., MacKenzie, M. D., and Gjerstad, D. H. (1999). Ecological land

classification in the Southern Loam Hills of south Alabama. Forest Ecology and

Management, 114, 395-404.

2. Castaneda, F.

, Collaborative action and technology transfer as means of strengthening the

implementation of national-level criteria and indicators. In Criteria and

indicators for sustainable forest management, ed. R. J. Raison, A. G. Brown,

and D. W. Flinn, 2001, pp. 145-163. IUFRO Research Series No. 7. CABI

Publishing, Wallingford.

3. Castley, J.

G. and Kerley, G. I. H. The paradox of

forest conservation in South Africa. Forest Ecology and Management, 85,1996, pp35-46.

- Caswell, H. Matrix population models:

Construction, analysis and interpretation. Sinauer Associates,

Sunderland,1989, pp 45