V.S. Savenko1, A.G. Silivonec2,

S.A. Ermokovec2

1 Doctor of technical sciences, Professor

MSPU named after I.P. Shamyakin,

Mozyr, Republic of Belarus

2 Undergraduate of physics and engineering faculty

MSPU named after I.P. Shamyakin,

Mozyr, Republic of Belarus

THE CONTRIBUTION OF THE PONDEROMOTIVE FACTORS IN THE

PHENOMENON OF ELECTROPLASTICITY OF DEFORMATIONAL MAGNESIUM

The paper

presents the results of research of influence of pulse current on the implementation

of electroplastic deformation. We have chosen magnesium as a material. It is

widely used in modern technology due to its low density, which can

significantly reduce the weight of components and structures. Magnesium is

widely used in the aviation and automotive industries.

The

article presents calculations of the ponderomotive factors of its own magnetic

field and electric field inside a conductor when implementing a multipass electoplastic

rolling of magnesium.

Introduction. There

are a number of factors of secondary force pulse current that affect the

plastic deformation of the metal under mechanical stress above the yield

strength such as the pinch effect occurring under the influence of its magnetic

field current and the polarization of electron subsystems of the metal with the

creation of the transverse electric field of Hall, preventing further

compression of electron plasma.

Skin

effect implements the reduction of the amplitude of electromagnetic waves as their

penetration into a conducting medium at the flow of high frequency alternating current

(AC) through the conductor creating the uneven distribution over the cross

section of the current density with a decrease in axial areas and increase near

the conductor surface. And it is associated with the he rate of diffusion of

the magnetic field in the metal and the presence of characteristic time τp of

magnetic field penetration in the conductor with current. [1]

It

should be noted that during the electroplastic deformation in addition to the secondary

pinch and skin effects in transmission pulse of electric current, there is a

thermal softening of the lattice, the calculation of its parameter for the considered

duration of the current pulses (10-4 - 10-5 s) is not

significant.

Pinch and skin effects. Electroplastic deformation implemented by multipass rolling of

magnesium (35 transitions) when

passing through the metal the pulse current density of 105 A/mm2,the

duration and pulse repetition rate of 104 s and 600 - 800 Hz. Final

geometrical parameters after 35 transitions: thickness is 1mm, width is 4mm.

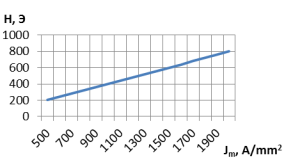

On the surface of the sample

self-magnetic field takes the maximum value (fig. 1a):

![]() , (1)

, (1)

where ![]() is amplitude value of the current in the conductor, then:

is amplitude value of the current in the conductor, then:

![]() , (2)

, (2)

where ![]() is the cross-sectional area of the

conductor.

is the cross-sectional area of the

conductor.

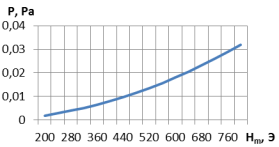

Mechanical pressure on the surface of

the sample for the electron plasma compression is equal to (fig. 1b):

![]() , (3)

, (3)

where![]() is mechanical pressure (Pa),

is mechanical pressure (Pa), ![]() is magnetic permeability for magnesium 1,257·10-6

is magnetic permeability for magnesium 1,257·10-6 ![]() .

.

Maximum axial force![]() from the pinch-effect is equal to:

from the pinch-effect is equal to:

![]() , (4)

, (4)

where ![]() is maximum axial force,

is maximum axial force, ![]() is Poisson's ratio equal to 0,27,

is Poisson's ratio equal to 0,27,

![]() is mechanical pressure,

is mechanical pressure, ![]() is

cross-sectional area of the sample.

is

cross-sectional area of the sample.

A special role in the phenomenon of electroelasticity

played by the material of sample and its conductivity, the rate of diffusion of

the magnetic field in the sample, which respectively determines the magnitude

of the pinch-effect. The value of pinch-effect depends on the circular

frequency which is 600 - 800 Hz.

Q factor should be small, such as when![]() is the value of

is the value of ![]() . [3, 4] Pulse duration should be

minimal in this case, it was τ = 10-4s.

. [3, 4] Pulse duration should be

minimal in this case, it was τ = 10-4s.

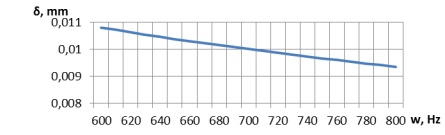

The thickness of the skin layer for the sample of magnesium

was determined as (5):

![]() , (5)

, (5)

where ![]() is the thickness of the skin layer,

is the thickness of the skin layer, ![]() is magnetic

permeability of magnesium,

is magnetic

permeability of magnesium,

![]() is conductivity

of magnesium,

is conductivity

of magnesium, ![]() is pulse

repetition rate.

is pulse

repetition rate.

Then, the thickness of the skin layer at 600 Hz: ![]() .

.

The thickness of the skin layer at 800 Hz: ![]() .

.

It is obvious that at sufficiently

high frequency ω, the thickness of skin layer can be very small (fig. 2).

à) b)

Figure 1 - a)

Ñhange of the self-magnetic

field of current h on the surface of magnesium at different values of current

density Jm; b) Modification of mechanical pressure p on the surface of

magnesium at different values of its own magnetic field current n

Figure

2 - Ñhange of magnitude of the skin layer δ from

the circular frequency ω

Conclusion.

To achieve high pinch effect, it is necessary to select such a frequency of

current pulse, so that the magnetic field does not have time to substantially

penetrate the surface of the sample. When the deformation of the sample occurs due

to the pinch effect, magnetic field diffuses the crystal, the speed of

diffusion depends on the conductivity of the metal and the frequency of the

current. At the same geometry of the samples, the pinch effect is stronger on

the material that has high electrical conductivity. Thus, the pulse current in

addition to electronic plastic action and exerts a ponderomotive effect on the

deformable material (compression of the sample with its own magnetic field and

excitation of elastic waves with a repetition rate of pulsed current). [1, 2].

Bibliography

1. Savenko, V. S. Mechanical twinning and electroplasticity

of metals in terms of external energy impacts : monograph / V. S. Savenko. – 2nd

ed. – Minsk : BGAFK, 2003. – 203 p.

2. Roshchupkin, A. M. About the influence

of electric current and magnetic field on interaction of dislocations with

point defects in metals / A. M. Roshchupkin, I. L. Bataronov // Solid state

physics. – 1988. – V. 30. – ¹ 11. – 3311 p.

3. Baranov, U. V. Physical basis of

electropulse and electroplastic treatments and new materials / Y. V. Baranov,

O. A. Troitsky, J. S. Abraham,

A. D. Shlyapin – M. : MOSCOW STATE INDUSTRIAL UNIVERSITY, 2001. – 844 p.

4. Troitsky, O. A. Fundamental and applied

research of electroplastc deformation of metals / O. A. Troitsky, V. S. Savenko.

– Minsk : IVC, 2013. – 375 p.

©

Savenko V.S., Silivonec A.G., Ermokovec S.A., 2016