Techniczne nauki / 6. Electrical engineering and electronics

Candidate of Technical Sciences Sukhar'kov O.V.

Odessa National Academy of Telecommunication named

after O.S. Popov,Ukraine

Sound generation in

the modified hydrodynamic radiator

Currently stream hydrodynamic radiators

(HDR) are used to enhance the efficiency

of various physical processes [1, 2]. Among the

advantages of data converters there are high energy intensity (the ratio of radiated power

to mass), low cost of radiators manufacture, small

size and simple maintenance. Stream HDRs are

conventionally divided into uniflow and counterflow converters [1]. For HDRs of

the two types the sound generation mechanism is explained by pulsations of

localized two-phase region and transverse bending self-oscillation of

axisymmetric jet shell [3]. The author designed and developed a modified HDR with a step obstacle and circular gap nozzle in the form of coaxial discs [4].

In the modified HDR flat

submerged axisymmetric jet interacts with a stepped obstacle, which has square niche

in front of it [4]. The process of sound generation in the interaction of the incoming flow with a

rectangular niche is analyzed [5 – 8]. In the case of

small flow rates ![]() , when the Reynolds number

, when the Reynolds number ![]() (

(![]() – kinematic liquid viscosity) does not exceed

– kinematic liquid viscosity) does not exceed ![]() there are stable

vortices formed inside the niche (one or two). With

this flow mode around the niche

no effects associated with the generation of sound arise. Significant increase in

Reynolds number leads to oscillation of the vortex at the aft wall of the niche

and related vertical oscillation of the shear layer over the niche with a certain

period

there are stable

vortices formed inside the niche (one or two). With

this flow mode around the niche

no effects associated with the generation of sound arise. Significant increase in

Reynolds number leads to oscillation of the vortex at the aft wall of the niche

and related vertical oscillation of the shear layer over the niche with a certain

period ![]() . Frequency of acoustic oscillations excited by the flow is substantially

proportional to the flow velocity and inversely proportional to the length of

the niche. This confirms the fact that the niche being flown around may be referred

as an acoustic generator, in which some part of the flow self-oscillations is excited

by aerohydrodynamic feedback [5, 8].

. Frequency of acoustic oscillations excited by the flow is substantially

proportional to the flow velocity and inversely proportional to the length of

the niche. This confirms the fact that the niche being flown around may be referred

as an acoustic generator, in which some part of the flow self-oscillations is excited

by aerohydrodynamic feedback [5, 8].

At higher Reynolds numbers (about ![]() ) it was found that in

addition to the above mentioned mechanism of sound generation, there is another

mechanism associated with abrupt periodic release of vortex from niche into the

flow [5]. The reason of the phenomenon is the ongoing oscillations

of the shear layer that last for some time while the layer is swept away by

flow beyond the niche. In English literature the mechanism is known as “wake

mode”. Feedback mechanism in the

self-oscillatory system has purely hydrodynamic nature [7]. However, in the

modified HDR an other kind of oscillation mode feedback is

implemented in comparison to the case of

the interaction of incoming flow and niche. This is due to the forming of two-phase

medium in the rectangular niche of HDR (liquid and steamgas microbubbles).

) it was found that in

addition to the above mentioned mechanism of sound generation, there is another

mechanism associated with abrupt periodic release of vortex from niche into the

flow [5]. The reason of the phenomenon is the ongoing oscillations

of the shear layer that last for some time while the layer is swept away by

flow beyond the niche. In English literature the mechanism is known as “wake

mode”. Feedback mechanism in the

self-oscillatory system has purely hydrodynamic nature [7]. However, in the

modified HDR an other kind of oscillation mode feedback is

implemented in comparison to the case of

the interaction of incoming flow and niche. This is due to the forming of two-phase

medium in the rectangular niche of HDR (liquid and steamgas microbubbles).

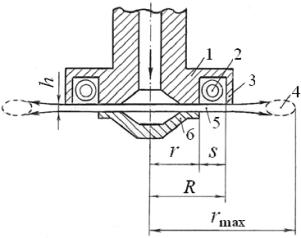

The proposed physical

model of HDR is

based on the idea of self-oscillations of submerged circular jet

plate in the presence of developed

cavitation (fig. 1).

à b

Fig.1. Modified

HDR: a – physical

model

b – photo of operating

radiator

Submerged axisymmetric jet 5

(fig. 1a) outflows perpendicularly to the axis of the radiator

from the slit nozzle radiator that is formed by coaxial discs of body 1 and

fairing 6. The jet is a kind of an elastic circular jet plate that makes

bending oscillations. We can assume that the inner edge of an circular plate is

rigidly clamped at the nozzle exit and the outer edge leans freely against the

stepped obstacle 3. Among the geometric parameters of the jet plate there are:

thickness ![]() , width

, width ![]() , inner radius

, inner radius ![]() and an outer radius

and an outer radius ![]() . Moreover, the plate thickness

. Moreover, the plate thickness ![]() is small in comparison to the

radius

is small in comparison to the

radius ![]() . Hydrodynamic parameters of jet plate are:

. Hydrodynamic parameters of jet plate are: ![]() – density, equivalent module of elasticity of a submerged jet and

its velocity at the nozzle exit. A niche with almost square cross-section is

made in the body 1 of the radiator. Stepped obstacle 3 (rectangular wedge) helps

to ensure that due to the Bernoulli effect a part of the kinetic energy of the

jet is spent on the formation of primary toroidal vortex 2 in the niche. In the

center of the vortex region 2, the conditions for the cavitation are created. Therefore the niche is filled with two-phase

medium (liquid and steamgas microbubbles).

– density, equivalent module of elasticity of a submerged jet and

its velocity at the nozzle exit. A niche with almost square cross-section is

made in the body 1 of the radiator. Stepped obstacle 3 (rectangular wedge) helps

to ensure that due to the Bernoulli effect a part of the kinetic energy of the

jet is spent on the formation of primary toroidal vortex 2 in the niche. In the

center of the vortex region 2, the conditions for the cavitation are created. Therefore the niche is filled with two-phase

medium (liquid and steamgas microbubbles).

With increase of cavities

concentration the pressure inside of the niche increases and reaches critical

value. At this point, the deformation of the outer edge of the circular jet

plate and release of the contents of the cavitation region 2 to the external

environment takes place. This creates a secondary toroidal region 4 with

developed cavitation (fig. 1b). Cavitation bubbles

collapse in region 4 thus resulting in microshock waves in the surrounding

liquid medium. This leads to an increase of the generated acoustic signal.

After the cavities ejection the pressure inside the niche becomes smaller than

the hydrostatic pressure in the environment and the conditions for the vortex

formation are again formed in the niche. Further the described process repeats

periodically and pulsations of two-phase region 2 excite bending oscillations

in jet plate 5. Frequency

of

pulsations of cavitation region 2 depends on the jet velocity at the nozzle

exit. When the frequency of pulsations of region 2 and the proper frequency of

the jet plate 5 are the same the sound signal of maximum

level will be generated [4].

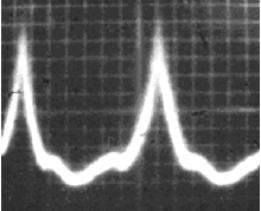

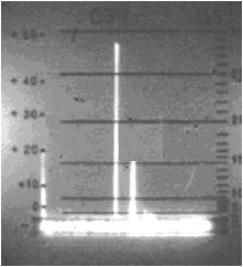

Fig. 2 demonstrates a sound

record and spectrum of typical sound signals generated

by HDR with optimal geometric

parameters and the optimum mode

of jet discharge. It is clear

(fig. 2a), that in this

case the radiator generates nonharmonic

acoustic signals in the form of short exponential

pulses. A significant fraction of the radiated sound energy falls on the fundamental frequency ![]() (fig. 2b). It has been found that the

radiator can be a source of powerful acoustic waves in the low sound frequencies

(fig. 2b). It has been found that the

radiator can be a source of powerful acoustic waves in the low sound frequencies ![]() [4].

[4].

à b

Fig.2. Typical sound

record (a) and the corresponding spectrum (b)

of the acoustic signal

from modified HDR

The

experimental investigations of HDR helped to reveal a

number of differences of sound generation in comparison with sound generation in

the interaction of the incident flow with a rectangular niche. First, in case

of the modified HDR fluid flow is formed by slit nozzle as

an elastic jet with small thickness ![]() [4]. Secondly, the radiator operates in the speed range

[4]. Secondly, the radiator operates in the speed range ![]() that results in the formation of cavitation area in the niche.

Thirdly, a modified HDR generates sound signal at a very

high Reynolds numbers:

that results in the formation of cavitation area in the niche.

Thirdly, a modified HDR generates sound signal at a very

high Reynolds numbers: ![]() . Furthermore, with increase of the jet velocity at constant geometrical

parameters of HDR the frequency of the main sound tone

generated by the HDR decreases. The latter fact is contradicts

completely to the classical laws that are specific to a aerohydrodynamic sound radiators.

. Furthermore, with increase of the jet velocity at constant geometrical

parameters of HDR the frequency of the main sound tone

generated by the HDR decreases. The latter fact is contradicts

completely to the classical laws that are specific to a aerohydrodynamic sound radiators.

To answer the

question, what makes a flat axisymmetric jet perform strictly periodic

oscillations, i.e. operate in a self-oscillation mode, we use the analysis of article [3]. Since the wave size of oscillating circular jet

plate is substantially smaller than the wavelength, its outer surface is loaded

by an impedance that has mainly mass character. In contrast, the inner surface

of the plate is loaded by an impedance having an elastic nature. Moreover, due

to the rather high ductility of two-phase medium, the corresponding elasticity

may be relatively small. As the result a kind of resonance acoustic system

consisting of three series-connected elements: elasticity – jet plate – mass is created. Clear enough, it

has its proper frequency, which will be imposed on the transverse oscillations

of an circular plate. This is the physical mechanism of self-oscillation

feedback of jet plate, the nature of which in this case is purely acoustic.

Literature:

1. Dudzinski Yu. M.

Axial-symmetric hydrodynamic radiators used for fluid cavitation threshold

measurement / Yu. M. Dudzinski, O. V. Sukharkov, N. V. Manicheva // The IVth

International Hutsulian Workshop on Mathematical Theories and their

Applications in Physics & Technology, 28 October–02 November 2002: The

materials of conf. – Kyiv: TIMPANI, 2004. – P. 275 – 286.

2. Ñóõàðüêîâ Î.Â. Ïåðåäà÷à äèñêðåòíîé èíôîðìàöèè â ãèäðîàêóñòè÷åñêèé êàíàë

ñâÿçè ñ èñïîëüçîâàíèåì æèäêîñòðóéíûõ ïðåîáðàçîâàòåëåé / Î.Â. Ñóõàðüêîâ // Öèôðîâ³

òåõíîëî㳿. – 2011. – ¹ 9. – Ñ. 100 – 110.

3. Âîâê È.Â. Î âîçìîæíîì ìåõàíèçìå àâòîêîëåáàíèé

â ñòðóéíûõ ãèäðîäèíàìè÷åñêèõ èçëó÷àòåëÿõ ñ ðàçâèòîé êàâèòàöèåé / È.Â. Âîâê, Â.Ò.

Ãðèí÷åíêî, Þ.Ì. Äóäçèíñêèé // Àêóñòè÷íèé â³ñíèê. – 2008. – 11, ¹ 2. – Ñ. 16 – 23.

4. Ñóõàðüêîâ Î.Â. Àêóñòè÷åñêèå

ñâîéñòâà ìîäèôèöèðîâàííîãî

æèäêîñòðóéíîãî ïðåîáðàçîâàòåëÿ â óñëîâèÿõ ãèäðîñòàòè÷åñêîãî äàâëåíèÿ / Î.Â. Ñóõàðüêîâ //

Ýëåêòðîíèêà è ñâÿçü. – 2012. – ¹ 5(70). – Ñ. 77

–

87.

5. Krishnamurty K. Sound radiation from

surface cutouts in high speed flow. PhD thesis / K. Krishnamurty. – California : Inst.

Technol. Press, 1956. – 76 p.

6. Higdon J.J.L. Stokes flow in arbitrary two-dimensional: shear flow

over ridges and cavities / J.J.L.

Higdon // J. Fluid Mech. – 1985. – N 159. – P. 195 – 226.

7. Rowley C.W. On self-sustained oscillations in two-dimensional compressible flow

over rectangular cavities / C.W. Rowley, T. Colonius, A.J. Basu // J. Fluid Mech. – 2002. – N 455. – P. 315 – 346.

8. Larcheveque D.L. Large-Eddy Simulation of flows past cavities / D.L. Larcheveque, P. Comte, P. Sagaut // Southampton, February 25. – AFM research group seminar, 2004. – P. 13 – 21.