Karachun V.V.

National Technical

University of Ukraine “KPI”

A GYRO OF THE ÄÓÑÓ-CLASS IN CONTROL

SYSTEM OF AIRCRAFT

In

control systems of hypersonic aircraft which are controlled by launch vehicles

(LV), cruise rockets, are widely used the so-called “float gyroscopes”. These

float gyros are structurally released from the main disadvantages of "dry" devices - significant (and,

more important, variable) moments of the dry

friction force on the outgoing axis and unacceptably high sensitivity to shocks

and vibration, especially undesirable for integrating gyroscopes. The main

difference of the float modifications is a movable part of the device immersed

in heavy organofluoric (specific gravity 1,9•103 Nm -3)

or organochlorine (specific gravity 2,7·103 Nm -3)

fluid. The gyromotor was located in a sealed cylindrical float, filled with

helium or hydrogen. By means of longitudinal pins the cylindrical float is

installed in the outer, also sealed, coaxial circular cylinder, which serves as

the body of the device. The supports of moving parts in some cases are carried out on the rocks.

Such technical

solutions are typical for a number of designs. Floating devices, unlike float,

have no excessive weight.

The

clearance between the lateral surface of the float and its body is too small

and is about 0,2 mm in the radial

direction. High viscosity of the fluid and a small size of the working

clearance allow providing a required damping factor in the integrating

gyroscope.

All

following conclusions will be made focusing on specific technical realization

of commercial manufacture by the aviation industry this float device. For

example, we will take into consideration the gyro angle rate sensor ÄÓÑÓ-30Â,

and which is designed for use in aircraft of a long-lasted operation.

As to

the principle of operation the device is inertial, that it does not require a

contact with the environment. Dynamic properties of the sensor are described by

an oscillatory link. Technical performance of the ÄÓÑÓ device

is a poly-unit structure. The ÄÓÑÓ purpose is to

measure the angle rate of hypersonic aircraft. The configuration of the device

is shown in Fig. 1. The measuring range of angle rate is of ![]() 30 deg s-1. The

sensor threshold of ÄÓÑÓ-30Â is about 0,45

deg s-1.

30 deg s-1. The

sensor threshold of ÄÓÑÓ-30Â is about 0,45

deg s-1.

Brief technical characteristics of standardized

gyroscopic sensor for angle rate

a) The sensor

normally works fine from power sources: 3-phase

AC voltage of 36 V frequency of 400 Hz (for the gyromotor) and direct current voltage 5 ÷ 30 V (for potentiometer).

a) The sensor

normally works fine from power sources: 3-phase

AC voltage of 36 V frequency of 400 Hz (for the gyromotor) and direct current voltage 5 ÷ 30 V (for potentiometer).

It is

possible to supply the potentiometer with AC voltage 5 ÷ 30 V (rms

value) at up to 2000 Hz.

b) The

sensor’s readiness to work is no more than 50

seconds. At the 10-second forced

supply 54±3 B (for the sensors with supply of gyromotors 36 B 1000 Hz) time of

readiness does not exceed 20 seconds.

c)

Alternating current consumption per phase is less than 0,3 A.

d) The

sensor threshold is no more than 0,45 deg

s -1.

e) The

angle rate range is ± 30 deg s -1.

e) The

dependence of the output signal on the angle rate at the potentiometer supply

with voltage 27 V is in the product certificate.

When

the potentiometer is supplied with other, not 27 V, voltage within 5

÷ 30 V the output signal is recalculated by the formula –

where ![]() – potentiometer

with voltage 27 V;

– potentiometer

with voltage 27 V; ![]() - voltage, not 27

V within 5 ÷ 30 V;

- voltage, not 27

V within 5 ÷ 30 V; ![]() – the output

signal when the supply of the potentiometer is of voltage 27 V.

– the output

signal when the supply of the potentiometer is of voltage 27 V.

i) The

sensor operates in the temperature range from + -60ºC to 60ºC.

c) The

sensor is vibrationproof in the frequency range from 5 Hz to 2000 Hz with

overload up to 30 g.

i) The

sensor is resistant to overloads up to 35

g.

k)

Frequency of own undamped oscillation is within 14 - 21 Hz.

l) The

resistance of the potentiometer is 800

ohms ± 20%.

m) The

ratio of amplitudes in half of the period in the temperature range is up to + -60ºC 60ºC equal to 0,05 ÷ 0,5.

n) The

permissible current in a circle of loads of the potentiometer does not exceed 0,03 A.

o) The

weight of the sensor is not more than 4,2

N.

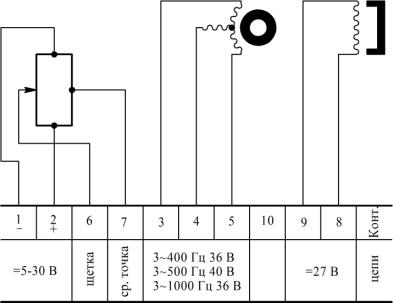

The

electrical circuit of the sensor of the ÄÓÑÓ- class

![]()

![]()

![]()

![]()

When

connected to the torque sensor (contacts 9 and 8) DC = 27 V, polarity

"-" on contact 9 and "+" on contact 8 is equivalent to the

effect of the sensor in the direction "clockwise"

on the angle rate.