Акшолаков Е.Б

The device

wchich recoveryexhaus gas purification system of catalyst

In this

paper we consider the path of modernization of diesel truck engine cleaning

system. Combined system of neutralization of

working gases of diesel engine, containing catholic neutralization allows to

bring down the troop landing of harmful components in an environment. Also in

case of obstruction of catholic neutralization the regeneration of liquid

solution is considered, for renewal of capacity of catalyst.

A starter is an electric, pneumatic, hydraulic,

an internal-combustion engine in case of

very large engines or other device used for rotating an internal-combustion

engine so as to initiate the engine's operation under its own power.

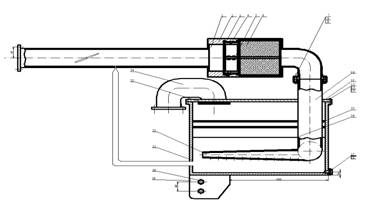

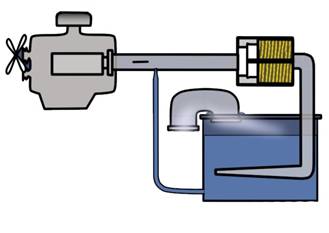

1- picture. The device

which neutralize the used gases

Internal-combustion

engines are feedback systems, which, once started, rely on the inertia from

each cycle to initiate the next cycle. In a four-stroke engine, the third stroke releases energy

from the fuel, powering the fourth (exhaust) stroke and also the first two

(intake, compression) strokes of the next cycle, as well as powering the

engine's external load. To start the first cycle at the beginning of any

particular session, the first two strokes must be powered in some other way

than from the engine itself. The starter motor is used for this purpose and is

not required once the engine starts running and its feedback loop becomes

self-sustaining.

The

system of neutralization of a diesel

engine consists of neutralization catalyst.

It filled up with entrance and exit pipelines, liquid neutralization filled up with liquid, pipe

equiped with diffuser and connected with cover . the lid is situated on the

cover pipelines of catalyst neutralization on.it managed in the cabin of driver

and the diffuser of pipe is situated at

the back of cover. Cover will be open when

the engine worked on load. Around the diffuser will current division,

liquid in the pipe don’t be in the stream of worked gases. Worked gases go to

catalyst neutralization. There are will be clean from the oil

which appeared during the high temperature fire. Then it goes to liquid

neutralization. And filtered from aerosol. Engine was putted idling mode for

doing regeneration process.

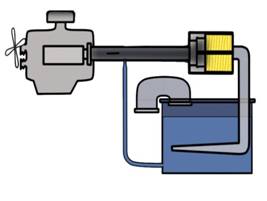

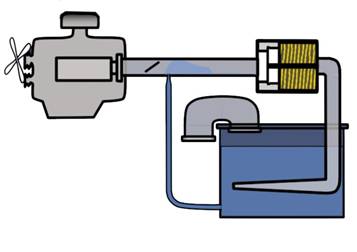

2-picture. Used gases from engine go to catalyst system

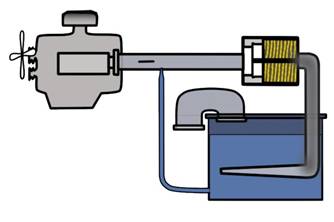

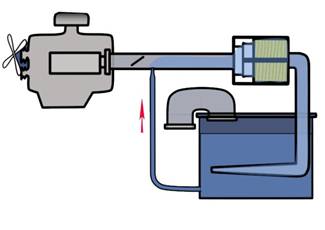

3-picture. Used

gases from engine go to the liquid through system

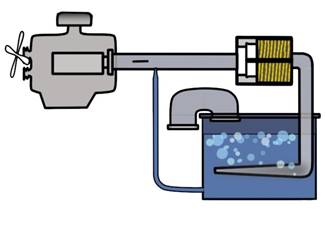

4-picture. Reaction between used gases from engine and liquid

5-picture. Escape

the used gases from engine

6-picture. Move

of regulate valves

7-picture. Neutralization liquid cleans the system of catalyst

Refferences:

1. Брозе,

Д.Д. Сгорание

в поршневых двигателях – М.:

Машиностроение, 1969. –

247 б.

2. Дәрібаев Қ.Б., Абдыкәрім Г.,Абдусалямов

Н.Н. Передвижная лаборатория для обслуживание и ремонта топливной аппаратуры

дизельных двигателей. (19) KZ

(13) U (11) 859 (51) G01N 33/22

(2011.01) B60P 3/00 (2011.01).

3. Автомобили – устройство и

техническое обслуживание / [А.Г. Пузанков] – М.: Академия, 2008. – 636б.