Raul Rink1, Dr. Sergey Shestakov2

1Oil Tech Production OY, Estonia, 11913, Tallinn,

Kressi Tee, 34 A,

E-mail: info@oiltech-nordic.eu

2Moscow state university of Technologies and

Management, Russian

Acoustical Society, Russia, 109004, Moscow,

Earth wal, 73,

E-mail: sdsh@mail.ru

The Cavitation Reactor with Symmetric Solid-State Oscillatory System of

the Acoustic Cell for Processes of the Food Sonochemistry

In

comparison with well-known, describes in the technical and patent literature

counterparts acoustic cavitation reactors suitable for use in food

sonochemistry, consider examples of the executed on the basis set forth in the

[1] of theoretical bases of projects reactors, mastering the production of

which started in Estonia and prepared in the republic of Belarus. They are

intended for physic-chemical treatment by ultrasonic cavitation true and

colloidal solutions, as well as disperse systems (emulsions and suspensions) by

initiating in them the sonochemical reactions and cavitation erosion of their

phases. In addition to these solutions, emulsions and suspensions in these

reactors can be processed chemically pure water and other chemically pure

solvents. In them is the impact on their

physical-chemical state of liquids, the intensification of in them chemical

reactions and initiation of new by changing the dipole-dipole and ion-dipole

interactions in their environments and phases, as well as increasing the

dispersion of multiphase systems, the destruction of bacteria and stabilization

of their number.

A typical example of a well-known classical design of

the reactor is, for example, a device, patented in the united states for nearly

half a century ago, and is called the "vibrations device" [2]. It is

equipped the reflecting wall, mounted so that his surfase is aimed in the

liquid, is in one plane with the surface of ultrasound radiator, surrounding

it. That is, surface of the front of ultrasonic wave, containing surface of the

radiator, coincides with surface of the wall, which has contact with liquid. The

second of reflective wall, located opposite first and radiator in the direction

of propagation wave is part of the corps of reactor. But the energy of

cavitation is the cause of erosion fracture of solids [3]. Erosion may be

subjected the structural elements design of cavitation reactor. The products of

erosion, falling in the treated liquids, can irreversibly change its physical

and chemical properties, which are strictly not allowed in the processing of

medicinal and food raw materials, as well as the medical products and food

products.

Housing this device is exposed to cavitation erosion,

caused by his contact with the perimeter of the cavitation areas, which related

to it work [4]. In addition, because the reflective the wall which is lying

opposite the radiator is part of the hard corps, it not may fully reflect the

elastic wave and its fluctuations partially transmitted the on the corps, which

leads to energy losses. The surface of the radiator and the walls are exposed

to erosion under the action of cavitation, which occurs near them.

Known the analog of reactor, consisting from a working

camera (the corps), the source of ultrasound

for creating cavitation and reflective wall, between which is placed

elastic layer, absorbing penetrating part of the ultrasonic wave and turns its

into heat [5]. In such a device rigid mechanical connection between reflective

wall and the corps is absent, which allows you to dissipate some of the energy

of ultrasonic waves in the film between them, and prevent the dissipation of

the energy of elastic waves on the cavitation near her. However, here, as in

the previous case, the walls of the corps are exposed to cavitation, formed in

the volume of fluid. Cavitation near the sides of the corps causes erosion of

the metal from which it is made and the ingress of its ions in the work

environment, which prevents the use of a similar reactor in the field of food

sonochemistry.

There is the design

of the cavitation reactor, representing a camera, the volume of which is

limited surface wall of corps, at least one of the reflective wall, at least

one emitter of acoustic waves and is filled with in the work the treated

liquids [6]. The size of the corps in the plane of any front of the elastic

wave is equal to the minimal positive root of a transcendental equation,

obtained by equating to zero singular generalized function, which approximates

the function of the integral of a dimensionless stiffness [4]. The root of this

equation determines the size of the housing, in which the potential energy

density of the cavitation at its surface is equal to zero. That is the erosion

of the walls of the corps in such a reactor is completely excluded. However,

the surface of the transducer ultrasonic waves still exposed to erosion, since

cavitation on its surface occurs because of the difference of the

amplitude-phase characteristics of radiated and fall on him the wave reflected îò opposite wall, about the means and ways of

equalization of which in the description of this reactor nothing no.

Known similar in

design cavitation reactor [7], where made the alignment by the largest

vibration amplitudes of fluids near reflective walls and these walls by

selection the acoustic resistance of the absorbing material layer between them

and the housing. This allowed to avoid cavitation also have the radiator

surface of ultrasonic waves and thus exclude it erosive destruction. But this

reactor also has the disadvantage of preventing its use for the treatment of

liquids in the food processing industry. The alignment of the amplitudes of the

oscillations of a radiator and reflecting walls and liquid near them here

achieved through the organization the regime, such as energy regime of

traveling wave, when the whole falling on the wall of the wave passes through

it, are not reflected back inside the reactor. The wall is here called

reflective only conditionally. A portion of the energy of wave which

transmitted through the wall into layer between her and the corps, scattered on

the internal friction of the material from which made this layer. And only part of the energy transferred by a wave

from the emitter to the treated liquid will be dissipated in it on cavitation.

Thus, the exclusion erosion of the material reactor is achieved here due to

the loss of part energy of the wave

radiated in the fluid of its source. For this additional costs are required

energy, replenishes these losses. And diffused in the layer between wall

and the corps the energy is converted into heat, which is gradually heats up

liquid, lowers threshold of cavitation and intensity of the latter [2]. This is

partly remedied in the acoustic cell cavitation reactor, where reflective wall

is regarded as an integral part of oscillatory system from the source of the

waves and located in this cell the fluid [8]. It is a solid-state mechanical

element with zero reactive components of acoustic impedance and high mechanical

q-factor. This allows to avoid thermal scattering, as the power, the equivalent

to dissipated on the internal friction, with her help of is transformed into a

reactive power, which can be compensated on the electrical side included in the

source of ultrasound electro acoustic transducer, which is acoustically

connected with the liquid and reactive sonoabsorber in the one oscillatory

system. But still, a part of this system

draws part of the oscillation power into the reactive power, that is, brings it

out the cavitation process in the other part of it - in the liquid, for whom,

and there is a cavitation reactor.

Such disadvantage is absent in the other

reactor, where all the parts of the vibrating system of acoustic cell is

solid-state [9]. In its design the surface to facing the transducer reflective

wall and itself emitting surface

belongs to the general solid-state resonator with resonance frequency equal to

the frequency of fluctuations of a radiating surface and posted near antinodes

of vibrational displacement, located between them fluid at a frequency of

resonance of its fluctuations. With such a cell in principle are possible to

implement a resonant mode of operation together with a liquid. It is clear that

the wave energy dissipated on the cavitation is the maximum. However, in [9]

there are no requirements to the structures providing such a regime. There

installed the distance between the planes of the resonator with which the

oscillations propagate in fluid equal to the length of their waves in it. But

the distance between antinodes of oscillatory displacement of solid-state

resonator which are near them is specified equal to half of length of a wave in

the metal. That is, these surfaces are commit fluctuations in the fluid in

opposite directions. Using the method of summing up the oncoming waves, in

which acts a cavitation, as described in [10], we can calculate that in this

case the average on height of the reactor, the amplitude of the sound pressure

of the fluid in it will reach 87% from the average amplitude of the sound

pressure in each of the waves from these surfaces, if they escape into an

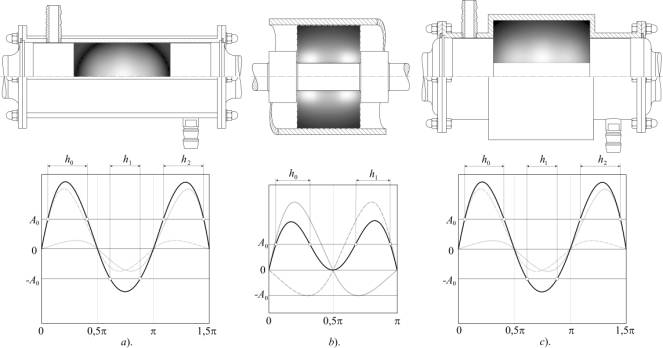

infinite half-space (see fig. 2). This is a

disadvantage, the main reason of which is that it created the conditions for

the resonance of the solid part of the oscillatory system of the acoustic cell

of reactor but conditions of resonance in the processed liquid is not provided.

Therefore, the power of a cavitation is not maximal possible, which are may be

get from these sources of fluctuations.

Considering the volume of

the processed in the reactor of the liquid, placed between the planes of the

solid-state resonator, with which in her emanate the fluctuations, as part of

oscillatory system the acoustic cell of reactor, you can create the optimum

conditions for the superposition of these oscillations. For such conditions the

formed near the antinodes of pressure of the total wave areas of cavitation [4]

will occupy a larger total volume of [1,10]. This can be done, given the

well-known fact [10,11], that is in the water flat-elastic wave gives able to

generate cavitation energy at a distance of not more than three half-waves, and

on the length of the half-wave fluctuations in metal (when the ends of segment

is fluctuate in opposite directions) fit about three half-wave of oscillations

of the same frequency in the liquid. That is, there is no sense to do the

volume of working chamber of the cell reactor length more than 1.5 length of

wave elastic oscillations in liquid, when the radiating surface are from each other by distance half wavelength fluctuations of

metal. Then the height of the acoustic cell (the distance between the radiating

surfaces) must be exactly equal to half the length of wave oscillations of

metal on the same frequency. Such conditions is easier to implement when the

solid part of oscillatory system of the acoustic cell is symmetrical about the center of mass, that is, the sources of

fluctuations (converters) are located on both sides of the volume of treated

water in the reactor. It is known [3] that the geometrically symmetric relative

to its center of mass of a system of elastic fluctuations holds better

resonance. Education cavitation erosion of radiating surfaces for it with virtually no will.

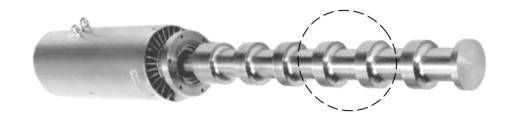

Using the

mathematical model of cavitation reactor and the principle of similarity of the

cavitation processes, described in the first chapter, can compare such a

reactor with a benchmark by arming the computer experiment. The Estonian

company "Oil Tech Production OY"

(Tallinn) made a reactor with two converters connected to one power supply

(ultrasonic generator) and doing of coherent oscillations [12], which form the

standing elastic wave by in the flow water through workspace. He is shown in

fig. 1 and consists of the camera body 1, which is made from the standard

seamless stainless steel pipes of the outside diameter 90 mm, a wall thickness

of 5 mm. Acoustic booster 2 with emitting the ends of a diameter of 79 mm,

such, as described in [13], is fixed in the casing with flanges 2 through the

seals with the help of studs 4. As the sources of fluctuations used converters

MPI 5050F-20L (5).

Fig. 1. Cavitation reactor of the

company Oil Tech Production OY,

described in [13]:

on the left is the design of the reactor;

on the right is a photo of the sample of the reactor, fixed on a

tripod.

|

Fig. 1. Cavitation reactor of the

company Oil Tech Production OY,

described in [13]: on the left is the design of the reactor; on the right is a photo of the sample of the reactor, fixed on a

tripod. |

As a

etalon was selected reactor, with a design similar to shown in the figure. 1.

This reactor is a reactor of a plane wave and is calculated by the formulas for

unsteady cavitation mode, since the time of its effect on the volume of the

processed water is very little for accounting of acoustic flows and under

hydrostatic pressure in it approximately equal to the atmospheric. Height of

the working chamber H standard (the distance between surfaces radiating the

coherent flat-elastic waves ) is selected to 1.5l in a liquid that has a static pressure ph = 1 atm,

the speed of propagation of flat-elastic oscillations c and density r close to the parameters of

chemically clean water (Fig. 2, a).

Total power consumption of radiators 2.4 kW.

Dimensions of the etalon chosen so that when consumed his converters of

electric power is the maximum amplitude of the sound pressure in the fluid

meets the concept of food sonochemistry. Through the working volume of the

reactor the fluid passes through the special nozzles.

The reactor,

with which made comparison (Fig. 2, b) contains a monolithic oscillatory system

of the acoustic cell, similar to the systems of the company Hielscher Systems

GmbH. The height of its single cell (the distance between the radiating

oscillations of the circular surfaces) is equal to two ïîëóâîëíàì in the liquid. It can contain a several of

such cells, components of total oscillatory system. The liquid in it passes

through the volume of the camera along the oscillatory system between it and

the wall of the chassis.

Reactors

UIP Hielscher Systems GmbH contain six cells, depicted in fig. 2, b, and source

- wave piezoelectric transducer is attached to the oscillatory system with one

side of her, as shown in fig. 3.

Fig. 2. a – design of the

etalon. The tonal pattern shows the distribution of the volume density power

cavitation erosion in the axial cross section; b – a fragment of a reactor

design firm Hielscher Systems GmbH.

Dimensions of working volume of a single acoustic cells are surrounded by a

dotted line; c –design of the reactor with a symmetric

solid-state oscillatory system of the acoustic cell. The tonal pattern shows

the distribution of the volume density power cavitation erosion. At the bottom

of figure on the charts shows the graphs of pressure:

▬ in emitted each

transformer waves, if they were distributed in an open half-space liquid;

▬ in the resulting wave of the

superposition of these waves. On the x-axis

shows the phase in radians at the resonant frequency of oscillatory system.

Fig. 3. Asymmetric

oscillatory system reactors UIP 4000 with a piezoelectric converter power

consumption 4000 kW in the housing

system of cooling (on the left).

Developed in accordance with the model [1] the reactor with monolithic

oscillatory system of the acoustic cell, the symmetrical about the center of

mass (Fig. 2, c), also consists of the camera body, maded from welded seamless

stainless steel pipes with a diameter 102 mm wall thickness of 6 mm and 146 mm

whis wall thickness of 7 mm, with a flanges with hole for fixing other flanges

with sealing by means of bolts and nuts (six on each side) waveguide

transformers with diameters of radiating surfaces 88 mm, which transmit the

vibrations sources (not shown) in the liquid with the a decrease of amplitude

and also interconnected barbell (Ø 32 mm) into a solid-state oscillatory

system. Compared reactors have a capacity of oscillation sources, the maximum

amplitude of the pressure of wave and the variance of the spatial distribution

of the power density of cavitation in the same as the etalon.

As a result of comparison were modeled performances for all these

reactors for the treatment of water used for the needs of food and

pharmaceutical industry, and pollutions her to the products of erosion in

relation to the indicators of the etalon reactor. Relative performance, so as

in all reactors used one and the same, the oscillation frequency f, is calculated as the ratio of works

average volume density of erosion capacity of cavitation in the working volume

of the chamber V

(1)

(1)

where qer – volume density erosion power of cavitation

in point of space êàâèòèðóþùåé

fluid with coordinates x, a, y in

the volume V of the product the

indicators of etalon reactor:

(2)

(2)

Instead of absolute

values of qer in the calculation of volumetric power density cavitation

erosion, because the liquid in the variants of one and the same, is used

contingent values:

,

(3)

,

(3)

where: a – the average of n cavitation areas of the

attenuation the total perturbations of pressure from all of the bubbles in the

point for which is calculated;

Svi = S×Shi – total volume of the i = 0...n cavitation areas (S - the

area of the front of the resulting wave in a reactor, equal to the square of

the surfaces radiating);

t

– average

of the dimensionless time of arrival perturbations of pressure from all the

bubbles n cavitation areas in this point;

– amendment to the phase of the cavitation field. Square

brackets denote a whole, and curly - fractional part of the number. Lengths of the free run of

fluctuations of the pressure from cavitation for period of the harmonic wave

are equal to the length of the wave.

– amendment to the phase of the cavitation field. Square

brackets denote a whole, and curly - fractional part of the number. Lengths of the free run of

fluctuations of the pressure from cavitation for period of the harmonic wave

are equal to the length of the wave.

Dimensions hi

cavitation areas on the beam of the waves were calculated, as recommended

[1,10] in angular units phase as the diference between the values of the even

and odd positive roots of the transcendental equation:

![]() (4)

(4)

where: Àmax, À0 – the maximal amplitude of the sound pressure the

wave when the radiation of fluctuations doing in half-space of the liquid and

the threshold for the education of cavitation, respectively; h

– scattering coefficient of the energy of the waves on the cavitation [11]. In

the linear units, they were translated by dividing the on wave number 2p/l.

Water pollution the products of erosion calculated proportional to the integral

value volume density erosion power E

in contact with water metal surfaces of the reactors. For reference it is equal

to:

(5)

(5)

and for compared

reactors:

(6)

(6)

where: R2,

R1 – outer radius of

radiating surfaces and the radius of the connecting rod, respectively;

Í – the distance between the radiating

surfaces;

D – her diameter;

qer,1, qer,2, qer,3 – density

of erosion power of the cavitation in the points of the radius of a radiating

surface and in the points of rays are separated from the axis of symmetry at a

distance of diameter of the walls of the camera and the diameter connecting

rod, respectively.

The results of comparison in the values in relation to

the etalon shown in the table.

|

OPTION REACTOR THE

RELATIVE INDICATOR |

UIP (Fig. 2 b) |

Fig. 2 c |

|

The performance of water

treatment |

1,8 |

3,5 |

|

The variance of

the spatial distribution of the density of the power erosion* |

1,02 |

0,87 |

|

The erosion of

the elements of design |

2,5 |

3,9 |

*the variance was adopted as much as possible

close to 1.00.

From the table it can be seen that the reactor UIP 4000 which has 1,7

times more, than at etalon power consumption of the piezoelectric converter and

the same (slightly larger) the variance of the spatial distribution of the

density of power of the erosion in the

working chamber it has 1.8 times greater productivity of processing of water,

and 2.5 times larger erosion of the details of the construction. The reactor

with a symmetric oscillatory system acoustic cells with similar (slightly

smaller) the distribution of the density of power of the erosion in the chamber

has the performance in 3.5 times, and the erosion of the details of the

construction in 3.9 times higher than that of the etalon. In other words, the

change of these parameters is almost to proportion to each other. Thus, when

performing the above requirements to the size of the solid parts of oscillatory

system acoustic cell cavitation reactor his power of cavitation, performance

and cavitation erosion surfaces of the parts are increased proportionally,

which testifies to the fact that the absolute contamination of treated water

will not change, as it flows through the reactor proportionally faster, but

useless loss of energy elastic wave is reduced.

R E F E R E N C E S

1. Shestakov S., Babak V. // Applied Physics Research, V.4, No. 1, February

2012, pp. 64-77

2. Patent US 3519251, 1970

3. Knapp R., Daily J.

and Hammitt F. Cavitation.–NY: McGraw Book Company, 1970

4. Shestakov S. The

basic technology of cavitation disintegration.-M: EVA-Press, 2001 (in Russian)

5. Patent US 4618263, 1986

6. Patent RU

2209112, 2002

7. Shestakov S. et al.

// ÕIII session of the Ross.

Acoust. Society, Vol.1 .- M.: GEOS, 2003, p.p. 31-35 (in Russian)

8. Patent RU 2392047, 2010

9. Patent ÅÐ 1810747, 2007

10. Shestakov S. and Befus

A. Dep. VINITI, 840-B2008 (in Russian)

11. Physics

and technology of high-intensity ultrasound / Rozenberg L. (Eds.), Moskow:

Nauka, 1968 (in Russian)

12.

Shestakov S. et al. // ÕÕIV session of the

Ross. Acoust. Society, Vol.2 .- M.: GEOS, 2011, p.p. 90-96 (in Russian)

13.

Shestakov S. // Õ session of the

Ross. Acoust. Society, Vol.2 .-M.: GEOS, 2000, p.p. 115-119 (in Russian)