Òåõíè÷åñêèå íàóêè/5.Ýíåðãåòèêà

Kirpichnikova

I.M., Doctor of Technical Sciences, Professor

Vozmilova A.A., Postgraduate student

South

Ural State University, Chelyabinsk,

Russia

THE SYSTEM OF THE HEATING BUILDINGS FOR THE CONTINENTAL CLIMATE

Modern tendencies of power complex

development imply availability of effective solutions concerning contraction of

energy consumption levels. Here belongs the usage of energy-efficient

technologies on the basis of renewable energy sources. One of such solutions

can be represented in the form of conjugation of wind-energy set of vertical-axis type “Wind turbine-3” with the

wattage of 3 kW produced by State Rocket Centre “SRC-Vertical” Ltd. in Miass

city, Chelyabinsk region, and infrared membranous electric heater.

Wind-energy set is a technical device aimed at

conversion of wind power into electric power. The key elements are wind turbine

rotor with impellers, generator component, aerodynamic brake, hub group and

lattice girder (Fig.1).

Lattice girder Hub group Aerodynamic brake Generator component Rotor with impellers![]()

![]()

Figure 1. Vertical-axis turbine device

Rotational speed reaches a certain number of turns per minute, with a

further strengthening of the wind, is stabilized by the so-called aerodynamic

brakes, invented by "SRC-Vertical" scientists. To work in cold

conditions, such as in the Far North, the blades are equipped with special

coal-plastic slick, that prevents surface icing of blades. The hub contains a

specially designed bearing system that allows the maximum to reduce the losses

from the moment of resistance.

In the continental climate of Russia, on 16-20 meters mast, the average wind

speed is 5-6 m / sec. Given the optimal location of wind turbine (mountains,

coastal areas of seas and lakes, tundra, etc.), the speed can be up to 6.5 m /

sec. Wind turbine-3 at a speed of 6.5 m / s produces 1 kW of

instantaneous power [1]. This power can be used to energize the slick heater.

Membranous electric heater is aimed at

economical, highly comfortable and effective heating-up of accommodations,

office buildings and industrial enterprises. Heater is a multilayered polymeric

material inside of which a resistive heating unit and an aluminum shield are

integrated. The shield functions as a radiator for temperature equalizing on

the whole surface of the heater and as a radiating element. Heater is only an

element constituent of building up an infrared system of central heating and

separate usage of it and of other elements (heating controllers and heat-reflecting thermal insulator) is not

rational.

The system operation is as follows. When power is applied to the resistive

element, the latter is heated to 40-50 C°. The aluminum screen allows to

distribute heat evenly across the surface of heater. Ceiling surface areas in

this case must be closed with heater

elements on 65%. Further distribution of heat is due to radiant heat exchange (infrared

radiation).

Inside the room the slick is mounted on the ceiling surface and can be

closed almost with any kind of building decoration. Room temperature is

controlled by the thermo regulator manually, automatically

or remotely and requires no special maintenance. If necessary, a slick heater

can be installed in walls and under carpeting.

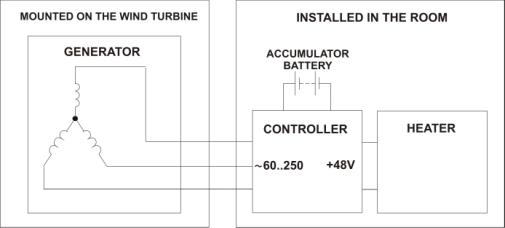

Heater is plugged-into a three-phase wind

turbine generator with the help of the

primitive regulator which allows to stabilize the constant voltage equalizing

48 V on account of bridging connection of four series-connected electric

accumulators with the voltage equalizing of 12 V. Wind turbine generator voltage due to its variability as to

electrical angle, electric frequency and amplitude changes from 0 to 300 V.

Constant voltage at the voltage regulator output is 48 V.

(Fig. 2).

This scheme allows to provide continual

heating-up of buildings according to construction norms and regulations. It

allows to predict the efficiency of the usage of such a system in wide

application and mass consumption as well. Moreover, it is important to choose

parameters of the wind turbine and heater to match according to their

characteristics.

On-peak loads and operation conditions of the system are characterized

by a considerable power demand – 200 W. per m![]() averagely. Such wattage cannot be provided by accumulator battery

(wind turbine), but it can be obtained through triggering mode. In its normal

mode wind turbine compensated the energy consumed. Besides, it is possible to

heat-up several rooms simultaneously or to diminish the line load during the

activation when using a controller allowing to gradually heat-up the building

on account of successive warming-up.

averagely. Such wattage cannot be provided by accumulator battery

(wind turbine), but it can be obtained through triggering mode. In its normal

mode wind turbine compensated the energy consumed. Besides, it is possible to

heat-up several rooms simultaneously or to diminish the line load during the

activation when using a controller allowing to gradually heat-up the building

on account of successive warming-up.

Figure 2. Heater connection scheme

Thus, the system can be divided into two parts:

1) wind turbine-3 - battery;

2) battery - heater;

The presence of a battery in the system is very important. In addition to

energy reserve battery will cover the peak power consumption during system

startup.

Wind Turbine works on accumulator battery. This section of the load

energizing chain is realized with a fairly high degree of difficulty based on

the intellectual controller. Based on the external parameters (battery charging

current, load current, the instantaneous available power), the controller

should ensure optimal operation of the system to be able to provide comfortable

living conditions.

Naturally, the better the room will be thermally insulated, the smaller

will be the magnitude of conductive heat loss and, consequently, the minimum

energy consumption, as in the mode of start-up and working. Therefore, the

maximum degree of insulation – the one of the important factors of high working

efficiency of the "Wind turbine-heater" system.

Directly load (heater) powered by 48

DCV. Heater heated to a temperature +45 0C.

On the surfaces whose temperature is different from + 45 0C, there is radiant heat

exchange. In turn, the intensity of this heat exchange will depend on the

characteristics and geometry of the surfaces themselves, and, specifically, the

degree of blackness (ε) and coefficient of irradiance (φ1-2). The higher the value ε (not to exceed 1) in the infrared spectrum,

the more heat can get the surface involved in the radiant heat exchange.

Coefficient φ1-2 shows the proportion of the

radiant flow incident on the heated surface of the total flow radiated by the

heating elements. This parameter is for all cases of possible arrangement of

surfaces in the room can be determined from the graphical dependences, which

makes it clear that with increasing height space of the room proportion of the

heat flow falling on the floor, decreases, and against to the walls increases.

Heating the room with the help of heaters does not allow drafts. In

addition, the walling must have the highest heat resistance. For this reason,

for example, do not use a system of "Wind turbine-heater" for room

heating with walling based on foam plastic ("fabricated" homes).

Using conventional thermo regulator can lead to an overestimation of the

level of energy consumption, as they have an infelicity of regulation ±2 îC. An increase of the setting temperature on 1 îC leads to an overestimation of energy consumption

by 5%. It is therefore advisable to use digital temperature sensors with

microcontroller control systems. In this case, the infelicity of regulation is ±0,1îC. Also useful to divide at least

two modes of heating. For example:

1) Power Save Mode (12-14 îC). The lower bound must not be

below the dew point. Such a mode will not unfreeze the room and significantly

reduce energy consumption during the absence of people.

2) Comfort mode (19-21 îC). Due to the high growth over a

short period of time creates conditions favorable for human habitation.

Switching between modes can be done remotely through GSM - modules, which

increases the attractiveness of such a system for remote areas. In addition, it

is known that at the infrared heating comfort is achieved at lower air

temperatures (17-18 îC) than at convective heating

method. Also infrared heat dries out the insulation materials, reduces their

coefficient of thermal conductivity, and consequently, lower heat loss than at

convective heat exchange. Running the system at low negative ambient

temperatures determines the largest by value (200 W/m2.) and the duration of peak energy consumption, which is extremely

undesirable. The system should be run at the first stable cooling (late summer

- early fall).

The lack of installed capacity (heating several rooms) is one of the main

problems. Provides several solutions:

- The use of non-priority load disconnection relay (some rooms are heated by

the residual principle);

- The alternate inclusion of rooms on equal intervals;

- The use of 2 or more wind turbines;

- Use of more powerful wind turbine;

- Conjugation of the "Wind turbine-heater" system with other

energy sources (solar battery, diesel - generator, electrical grids);

- The use of the "Wind turbine-heater" system as an additional

heating;

- Use a larger capacity battery;

- Reducing heat losses as well as electrical losses at the energy

transformation.

This heating

system can be applied to heat-up those

accommodations, which are situated considerably far from central heating

systems, electric power supply and gas-supply (country houses, farms, tourist

centers, fishing and hunting husbandries, caravans in temporary villages,

exploration crews, frontier posts and other similar objects). (Fig. 3).

![]()

Figure 3. Energizing of infrared slick

heater by wind turbine-3

It is efficient to use this system in cases when expenditures on

traditional central heating-up systems exceed expenditures on the solution of

this problem using wind turbine-heater. This system will be used effectively in

a continental climate, for example, on the North of Russia and Scandinavian

countries such as Finland, Sweden, etc.

List

of references

1. Kirpichnikova, I.M., Solomin E.V. Vertical axis Wind Turbine / / Journal

of South Ural State University “Vestnik”. "Energy" series.- 2008. -

Ed. 10, ¹ 26. - P.15-16.

2. Kirpichnikova, I.M., Solomin E.V. Panasyuk I.N. Conjugation of low power

wind turbine with the slick electric heater for room heating / / Journal of

South Ural State University “Vestnik”. "Energy" series. - 2009. - Ed.

12, ¹ 34. - P.74-77.