Ph.D., associate Professor Lydmila

Ignatovich

Belarussian State University

of Technology, Belarus.

Ph.D., associate Professor Lydmila

Dubovskaya

Belarusian State Academy of

Arts, Belarus.

Influence

of the interaction of hardener and mineral binding THE STRENGTH OF COMPOSITE

Introduction. It is known that

the waste from wood processing industries often burned, but the calorific value

of the sawdust is low enough and the use of soft waste in this capacity is the

least economically expedient in relation to other types of wood fuel. There is

more rational use of waste wood - as a raw material for the production of

composite materials in the mineral binder. A good mineral binder is a liquid

glass, which has high adhesion to wood, low cost and availability of raw materials.

Significant disadvantages of liquid glass are its low water resistance. Improve

the adhesive properties of sodium silicate and water resistance can be achieved

by modifying hexafluorosilicate sodium, which also accelerates the process of

setting and hardening of the liquid glass.

The main part. In order to

identify the reaction products hexafluorosilicate sodium silicate in the

presence of sawdust and without electron microscopic analysis were and IR

spectroscopic studies of the initial components and products of their

interaction. Infrared absorption spectra of the test compounds were recorded in

the frequency range of 400-4000 cm-1 by direct analysis of individual

substances without mixing with KBr. Spectra were obtained with single-beam

FT-IR spectrometer "FTIR-8601 PC". In the analysis we recorded the IR

absorption spectra of the compounds considered in the general case, the number

of absorption bands related to the vibrations of the ion or molecule, and the

frequency range of their occurrence. The results of these studies suggest that

the basis of the interaction of the starting compounds (water glass and

Na2SiF6) is a chemical reaction oc-Penitent by equation 1:

2(Na2O·3,2SiO2∙nН2О) +2Na2SiF6

® 8NaF + SiF4↑+

7,4(SiO2∙nН2О) (1)

The

reaction of proceeds sufficiently quickly (within 10-15 minutes) and

irreversible. Since the content of NaF in the solid product interaction (TPR)

Na2SiF6 and Na2SiO3 24 hours was the same as after the 10-minute interaction,

the solid product and the parent compounds were analyzed for silicon content by

electron microscopy analysis using scanning microscope with a microprobe, which

allows to determine the chemical composition of the element by element of the

objects. It was found that the total of the total silicon in the initial

product (Na2SiF6) + (Na2SiO3) is 25.28 wt.%. This exceeds the total silicon

content in the solid product interactions on the value of 12.39 wt.%. This

difference corresponds exactly to the total silicon content in the gaseous

product of interaction. The above scheme can be balance (Equation 2):

(Si Na2SiF6+

Si Na2SiO3) - Si = Si SiF4 (2)

Or,

based on 100 wt. h of liquid glass and 16 wt. h hexafluorosilicate sodium

balance in distribution of silicon is (Equation 3):

(5,51 +

2,38) – 6,7 = 1,20 wt. % (3)

The

presence of silica in the solid product is confirmed by the interaction of the

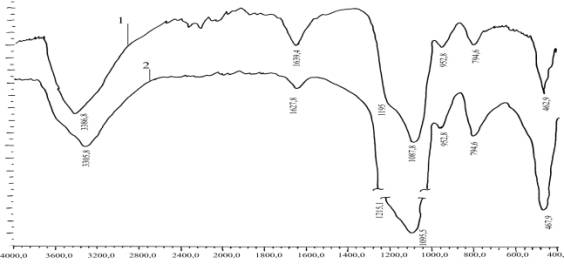

initial components of IR spectroscopic studies. IR spectra were analyzed

products are shown in Figure 1. Confirmation that the mixture and Na2SiO3

Na2SiF6 in the presence of H 2 O is the reaction of interaction, leading to

destruction and SiF62-SiO32-anions to form SiO2, is the absence in the IR

spectrum of the mixture Na2SiF6 Na2SiO3 absorption bands corresponding to the

vibrations of the anion SiF62--733, 494 and 475 cm and SiO32-1018, 900, 770,

474, 436 cm (Fig. 1). View of the IR spectrum of a mixture Na2SiF6 Na2SiO3

after the interaction is almost identical to the IR spectrum of amorphous SiO2.

The absence in the IR spectrum of the mixture and Na2SiO3 Na2SiF6 absorption

bands corresponding to the vibrations of NaF, due to the fact that its content

of impurities NaF (equation) below the lower limit of detection of its

appropriate instruments [1].

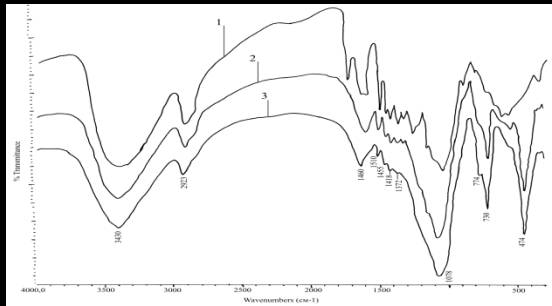

The

study results assume that the adhesion of the particles of wood composite [2]

due to the formation of a stable crystal structure (Fig. 2), consisting of

molecules of SiO2 ∙ 2H2O and NaF, formed by the interaction of sodium

hexafluorosilicate (Na2SiF6) and sodium silicate (Na2SiO3) for the above-given

reaction. At the same time, the IR spectra of composite materials designed

purpose [2] found the absorption bands corresponding to vibrations of the anion

SiF62-730, 490 and 474 cm (Figure 2). This indicates the presence of sodium

hexafluorosilicate in the resulting materials. Above will most likely reaction

of Na2SiO3 Na2SiF6 and adding filler - sawdust - occurs is not completely due

to possible steric hindrance arising from the interaction of components and

wood bonding with each other [3].

Fig. 1

IR absorption spectra1 2Na2O • SiO2 · nH2O + 2 Na2SiF6;

2 - amorphous SiO2

Fig. 2

IR absorption spectra1 sawdust, 2 - the material of construction of 3 -

insulating material

Conclusion. Improving the strength of

materials produced by small pieces of wood and water glass in the presence of

sodium hexafluorosilicate, due to the formationnew hydrogen bonds with the wood

due to their participation in shaping the structure of fluoride ions present in

the anion SiF62-and have greater electronegativity. [4]

Increase

the water resistance of such materials sposobstvovuet reduction of hydrophilic

hydroxyl groups, clearly visible when comparing the IR spectra of the

"Silk-K", "Silk-E" and the original wood (wood of the

absorption band of the 3000 - 3700 cm-1 is much deeper and wider ). [3]

Literature

1. Атлас инфракрасных спектров поглощения

и рентгенографических данных комплексных фторидов металлов IV и V групп / Р.Л.

Давидович [и др.]; под общ. ред. Р.Л. Давидовича. – М.: Издательство, 1972. – 252

с.

2.

Дубовская, Л.Ю. Композиционный материал на основе древесных отходов и

минерального вяжущего / Л.Ю. Дубовская, А.А. Янушкевич // Известия Белорусской

инженерной академии. – 2004 – №2. – С.

29 – 30.

3. Карклинь В.Б. ИК-спектроскопия

древесины и её компонентов / В.Б. Карклинь, Е.Э. Охерина // Химия древесины. –

1981. – №4. – С. 38 – 44.

4. Жбанков, Р.Г. Инфракрасные спектры

целлюлозы и её производных / Р.Г. Жбанков. – Минск, 1964. – 338 с.