ABSTRACT

The principal manufacturers of

light water currently apply the method of distillation in rectifying columns. The

disadvantage of this method is the low separation coefficient. Multiple stages

are needed in order to significantly reduce the deuterium content which makes

the method expensive. We have designed the

electrolytical method with a recuperation unit

which allows reducing by 4-6 power consumption required for producing light

water comparing to rectification methods applied nowadays.

Keywords: deuterium

depleted water, light water, rectification, electrolysis, recuperation system, MHD

generator.

1. INTRODUCTION

The light

water in which the content of deuterium is lower compared to that in standard

mean oceanic water (SMOW D/1H=155.76 ppm) modifies the velocity

of chemical reactions, ions' solvation, their mobility, etc. Taking light water

leads to normalization of carbohydrate and lipid metabolism, weight

improvement, elimination of toxins from the organism. It is determined that the

taking such water improves work efficiency, physical activity, endurance and

resistance of organism [1, 2].

The

Institute of Medico-Âiological

Problems of the Russian Academy of Science has determined that deuterium-rich

water has stimulating effect on the organism' reproduction function and has no

toxic effect on laboratory animals' organisms, and a long use of deuterium

depleted water leads to diminishing the severity of radiation injuries caused

by gamma radiation every day exposure with low doses [3].

The main effect of light water

is a graded decrease of deuterium content in the body's liquids due to isotope

metabolism reactions. The use of water

with low deuterium content results in decrease of this element's concentration

in blood plasma, in erythrocytes and in homogenate of laboratory animals'

hearts. Such changes induce in their turn the decrease of pro-oxydant load in

organism and recover of pro-oxidant/anti-oxydant system balance which is

further accompanied with higher immunity of laboratory animals [4, 5].

2. Existing methods for obtaining light water

The principal manufacturers of

light water currently apply the method of distillation in rectifying columns

[7] which uses the difference in different mass isotopes' evaporation rate

which grows as the atom mass reduces. Light water has the boiling point in

normal conditions at 100.0 °Ñ, while heavy

water's boiling point is at 101.4 °Ñ. The study

describes a deuterium depleted water plant (fig. 1) consisting of the unit

of producing vapor from initial water 1, the unit for feeding water vapor

into the rectifying column 2, the unit of interaction vapor-liquid 3

with a contact device inside 4, of the unit for water vapor condensation 5.

The vapor pressure inside the rectifying column is from 0.05 to 0.6 bar,

the outcome of condensed light water is from 0.001 to 0.25 to the total volume

of water vapor fed through the column. The plant allows industrial production

of light water with the content of 1Í216O no less than 997.13 g/kg and with total content of 1Í217O, 1Í218O, 1HD16O,

1HD17O, 1HD18O, D216O,

D217O, D218O no more than 2.87 g/kg

of the total quantity of H2O.

The disadvantage of this

method is the low separation coefficient due to the complicated process of

maintaining a stable temperature of boiling liquid. Multiple stages are needed

in order to significantly reduce the deuterium content which makes the method

expensive.

Fig. 1 – Light water producing plant with a

rectifying column

Membranes

are also proposed to obtain light water [8]. The plant is shown in fig. 2 and consists of

the initial water tank 1, the pump 2 for feeding the initial water

into the filtering element 3, of the vessel 7 and flow regulator 6 in

the form of a laminar resistance. Inside the filtering element 3 the water

flow passes along the membrane 4 axe. Under the pressure amounting from 0.1 to

30 bar some water penetrates through membrane 4 and passes to the

vessel 7 in the form of light highly pure water. The second water flow

bypasses and regenerates the membrane 4, then is fed again to the

discharge 5 via the regulator of flows ratio 6. The produced volume of deuterium

depleted water is from 0.05 to 0.8 of the

total initial water volume. The content of light molecules of 1H216Î in the produced light water amounts to no less than

99.734 % of the total quantity of Í2Î, the concentration of 17O in the obtained

light water is no more than 372 ppm, and the concentration of 18Î does not exceed 1960 ppm.

The weakness of this

method is a high cost of membranes which require extra pure initial water and

wear out fast, and the method does not enable to reduce the deuterium content

below 117 ppm.

The weakness of this

method is a high cost of membranes which require extra pure initial water and

wear out fast, and the method does not enable to reduce the deuterium content

below 117 ppm.

Fig. 2 – Light water

producing plant with membrane

The crystallization method

allows reducing the deuterium content at most to 136 ppm which is good for

health but not enough for medical application. This method may be used as a

preliminary phase for further refinements.

Multiple other methods are

known which may be used to separate hydrogen isotopes [6], although most

of them have a low separation coefficient about 1.01, others are too

expensive in installation and operation. Thus, there is a need to design a more

cheap and effective method to produce light water.

3. New method for obtaining light water

We have designed a method for

producing water that is poor in heavy hydrogen and oxygen isotopes which bases

on the difference of oxidizing and deoxidizing potentials and kinetic

properties of hydrogen oxido-reducing process from light and heavy water [9-14].

The electrochemical method has been used earlier for the reverse process, i.e.

for obtaining heavy water in nuclear power industry.

The separation is carried out

as follows. Water is electrolyzed when most decomposed molecules are those

containing protium due to lower covalent link strength. Then water is

synthesized from an oxygen/hydrogen mixture rich in protium. In order to

increase the coefficient of separation and to reduce the hydrogen's overvoltage

the electrodes are made of nickel. The plant allows the outcome of product with

any specified depletion down to a very low deuterium content – 10 ppm.

The

method is implemented using various designs [9-14] and, contrary to other

methods permits returning a part of energy back into the production cycle which

importantly reduce the power consumption and thus to reduce the final product

prime cost.

The

energy may be recuperated using the following:

1. Fuel hydrogen/oxygen element [9-10].

The line is equipped with gas mixture separator including a membrane made of

palladium and silver installed between the drying unit and the fuel element,

and the electrolysis gases into water converter is designed as a low

temperature hydrogen/oxygen fuel element with ion exchange membranes providing

that the fuel element is electrically connected to the electrolyzer.

2. Gas turbine [11-12].

Electrolysis gases converter is designed as a high temperature gas turbine the

shaft of which is mechanically connected to that of the generator supplying the

power to the electrolyzer.

3. Magnetohydrodynamic

(MHD) generator [13]. The gas mixture is fed into a magnetohydrodynamic

generator where it is heated, being burned, up to 2700-3000 °Ñ. The formed plasma while passing through a magnetic

field produces electric power supplied into the electrolyzer.

4. Thermoelectrical generator [14].

It is

a leak-tight metal rectangular vessel having inside opposite partitions which

are offset relatively to each other in the way to prolong to maximum the

distance the gas passes. Thermoelectrical modules are fixed to the unit's

surface which converts a part of heat into electrical power by virtue of

Seeback's effect.

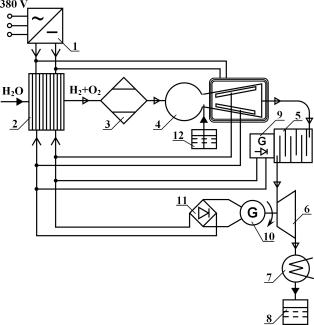

5. A

line using simultaneously a magnetohydrodynamic (MHD) generator,

thermoelectrical cooling generator and low temperature turbine [14] is

shown in fig. 3.

Fig. 3 –

Production line for obtaining light waterusing a MHD generator, thermoelectrical

modules and gas turbine

The alternative current from

an external power distribution network is transformed into direct current by

the power supply 1, then flows to the electrolyzer 2 into which

distilled water is also fed. The mixture of oxygen and deuterium-poor hydrogen

so formed in the electrolyzer, in order to prevent the reverse isotope exchange with water vapors, is passed through the

dryer 3 filled with regenerated water absorbing substance. Then the

dried gas mixture is fed into the MHD generator 4 in which it is heated,

being burned, up to 2700-3000 °Ñ and into which a

salt solution with the salt content required to produce drinking water is injected

from the vessel 10. The salt is ionized at that. The forming plasma passes

through a transversal magnetic field of the MHD generator, and Lorentz force

separates it into a positive and the negative flows which get onto the

appropriate electrodes, and the produced electric power is supplied into the

electrolyzer. The gas temperature is reduced down to 1000-1200 °Ñ. Then water vapor is fed into the cooling generator 5

in which it passes via a coil tubing with thermoelectrical generators attached.

After that the gas is fed into the turbine 6 where it rotates the shaft of

the generator 7 which produces the electric power that is supplied into

the electrolyzer through the rectifier 11. Then water vapors are fed into

the condenser 8 and then to the collector 9.

CONCLUSION

The use of the

electrolytical method with a recuperation unit allows reducing by 4-6 power

consumption required for producing light water comparing to rectification

methods applied nowadays. Thus we may draw a conclusion that in the nearest

time this method will became one of the main ways to produce light water.

This work was supported by the RF Ministry of

Education and Science no. 7.369.2011.

REFERENCES

1. G. Somlyai,

The biological effect of deuterium depleted water. A possible new tool in

cancer therapy, Anticancer Research

Journal. Vol. 21, ¹ 3,

2001.

2. G. Somlyai,

The biological effect deuterium depletion (Budapest,

Akademiai Klado, 2002).

3. D.V. Rakov The effect of water with low content of heavy stable

of hydrogen's isotope of deuterium and oxygen 18Î on the development of radiation injuries in case of

gamma radiation exposure at a low dose, Radiatsionnaya biologiya. Radioekologiya,

Vol. 4, ¹ 4, 2006, 475-479.

5. M.G. Barishev, A.A. Basov,

S.N. Bolotin, S.S. Dzhimak, S.R. Fedosov, V.U. Frolov, D.V. Kashaev, D.A. Lysak, D.I. Shashkov, A.A. Timakov

The assessment of antiradical activity of water with modified isotope

composition using NMR, EPR and mass-spectroscopies, Izvestiya RAN. Seriya

fizicheskaya, Vol. 76, ¹ 12,

1507-1510.

6. I.N. Bekman Radiokhimiya.

Razdeleniye izotopov (Moscow: MSU, 2006)

7. Patent

¹ 2295493 Russian Federation, IPC C01D5/00, B01D59/00, B01D59/02, B01D3/14. The process method and the

plant for light water production. / S.P. Solov’yev, – priority 28.05.2004.

8. Patent ¹ 2390491 Russian Federation, IPC C01B5/00, B01D59/00, B01D59/12, B01D61/00. The

process method and the plant for light water production. / S.P. Solov’yev, – priority 08.05.2007.

9. Patent ¹ 101648 Russian Federation, IPC B01D59/40, B01J25/02, C01B4/00. Production line

for obtaining bioactive water with low content of deuterium. / V.U. Frolov, M.G. Barishev, L.V. Lomakina,

S.S. Dzhimak, – priority 25.05.2010

10. Patent ¹ 2438766 Russian

Federation, IPC B01D59/40, C01B4/00, C02F1/461. Method for producing bioactive water with

low content of deuterium. / V.U. Frolov, M.G. Barishev, L.V. Lomakina,

S.S. Dzhimak, – priority 25.05.2010.

11. Patent ¹ 97994 Russian

Federation, IPC C02F1/00. Production line for obtaining bioactive water with low

content of deuterium. / V.U. Frolov, S.S. Dzhimak, – priority 25.05.2010.

12. Patent ¹ 2438765

Russian Federation, IPC B01D59/40, C01B4/00, C02F1/461. Method for producing bioactive water with low content

of deuterium. / V.U. Frolov, M.G. Barishev,

S.N. Bolotin, S.S. Dzhimak, – priority 25.05.2010.

13. Patent ¹ 106559

Russian Federation, IPC B01D59/00. Production line for obtaining bioactive water with

low content of deuterium. / V.U. Frolov, M.G. Barishev,

S.N. Bolotin, S.S. Dzhimak, – priority 22.02.2011.

14. Patent

¹ 113977 Russian Federation, IPC B01D59/40, C02F1/461. Production

line for obtaining bioactive water with modified isotope composition. / M.G. Barishev,

S.S. Dzhimak, M.A. Dolgov, L.V. Lomakina, V.U. Frolov, –

priority 17.11.2011.