Model of a temperature field

of preparation from a single thermal source at abrasive processing

Dyakonov A. A., Ermilov

S.A.

South-Ural State

University, Russia, Chelyabinsk

Only

thin layers of part blank are subject to sudden (impulsive) heat in the grinding

zone. That is why during description the temperature field the geometry of part

blank may be neglected, in other words for 3-D system it can be considered the

case of half-space heating by sources moving on the surface. As used here the

process of heat transmission mathematically comes to the second boundary

problem for heat conduction equation in the half-space. Integral Decision is known for

this linear model [1]:

(1)

(1)

ñ— thermal diffusivity of material; ρ — density of

material; χ — thermal diffusivity of material; D i — the scope of i-sources — abrasive

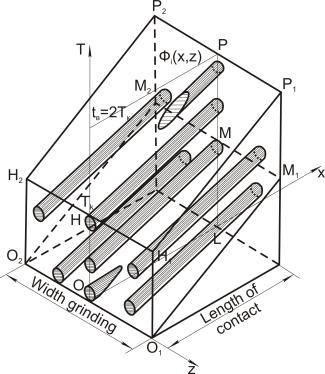

grain in XZT- system limited by surface Ôi (x,z)=0 (fig. 1);

q — intensity of heat source.

Fig. 1. The principle scheme of thermal sources influence

It is

rather complicated integral and not evaluated by famous special function.

As it

is researched by many investigators the theory of high-speed sources can be

used for grinding process offered by N.N. Ryikalin [2]. Using of this theory

allows decreasing the number of independent coordinates and reducing integral

equation for separately thermal source to following format:

(2)

(2)

U(y,z,t) — the

temperature in the moment t at the

depth of y with z–coordinate in breadth; λ — thermal conductivity of material;

l ç — the length of abrasive grain blunting area.

Starting

from the purposes of the research it is important to consider the temperature

of thin layers of part blank to the moment of biting the next abrasive grain.

By S.N.

Korchak [3] researched that for definition impulsive temperature it is required

to consider thin layers of part blank within the limits of 0,05-0,002 mm as

this depth is marginally allowed for scraping off material by single abrasive

grain.

Alongside

with this, change of temperature at the depth part blank surface in the

following diapason 0,002–0,010 mm are negligible as temperature drastic

recession is observed at the depth of higher than 0,015 mm [3].

Because

of it y=0 and we can come to 2-D system. As the result dependence (2) come to

the following equation:

(3)

(3)

This

dependence (3) describes the heating process from single thermal source. For

realizing cooling-down calculation the dependence (3) computes with zero

intensity of heat source (4).

![]() (4)

(4)

Taking

into account expression (4) we have get the dependence describing cooling-down

from single heat source (5).

(5)

(5)

In the

result taking into account dependences (3—5) the temperature from single heat

source — abrasive grain — can be described by system of equations (6):

(6)

(6)

The

equation (6) describes the heating and cooling-down process cause of single

heat source — abrasive grain taking into account flank flow-out at circle breadth.

However,

using of this integral for calculations involves difficulties even by computer.

Analysis

of the literature concerning thermal physics of solids makes clear that integral

(3) can be expressed by special

functions: error function erf(x) and integral exponential function Ei:

·

error function erf(x):

(7)

(7)

·

integral exponential function Ei:

(8)

(8)

The meanings of

these functions are learned [4]. As the result we have get:

(9)

(9)

q — intensity of

heat source; λ — thermal conductivity of material; a — the half of length

heat source (a=0,51ç); erf(x) —error

function;Ei — integral exponential function, z — coordinate of source endwise

z, ҳ — thermal diffusivity of material.

Using

the method of reflected sources [4] to describe cooling-down process is used

equation for heating (9) from which analogue equation subtracted with τ:

(10)

(10)

As the

result equation (6) can be signed by equations system (11):

![]()

There are

no difficulties concerning calculation of equation system (11) both by computer

and by hand.

Conclusion

Consequently

received spatial model rather exactly describes impulsive temperature field of

part blank unit section. At that, adaptation of superposition method and

parallel displacement of coordinates allow to research the temperature field of

part blank by grinding in any required time moment of it formation. And also it

allow to research heat spreading both cutting velocity vector direction and

transversely to it.

References

1.

Reznikov A.N. The Physics of cutting.

M.: Mechanical engineering, 1979. 288 p.

2.

Ryikalin N.N. Account and modeling of a

temperature field of a product at grinding // The

bulletin of mechanical engineering. M.,

1963. ¹1. P.74–77.

3.

Korchak S.N. Productivity of process of

grinding of steel details. M.: Mechanical

engineering, 1974. 280 p.

4.

Karslou G. The Thermal conductivity. M.: Science, 1964. 488 p.