Ph.D. S. Nurushev

Kostanai

state University A.Baitursynov .

Working body milling form justification.

The most significant drawback of milling of soil

cultivation tools is the high energy consumption and low productivity . One of the elements that determine

their power capacity and productivity

is the form of active working body (

blade) , because it affects the way to the formation of soil cuttings of a

certain size .

KGU named

after A.Baitusynov conducted research

in order to justify the form of T-shaped

experimental blade, which have right and left side folds on one leg ,

and perform the functions of both right -hand and left-hand serial Ã-shaped blades mounted

separately on the disc milling cutter drum.

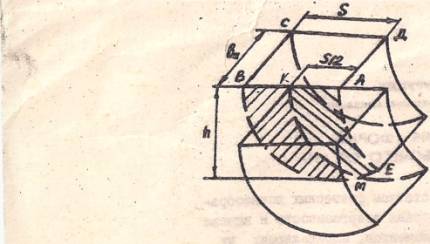

When separating the two serial blades supply half hour right blade passes

through the already preliminarily

clipped by leg left-hand blade (picture). It turns out that half of the supply portion AKE cut twice . In

view of the different sharps left and

right leg conditions for subsequent blade is not made easier, because leg working in a continuous medium with

considerable friction.

Total cut surface can be determined :

F =Fshear + Ffriction

+ Fbend=2h(S+δ bH)

δ - Coefficient taking into account the

difference between the milling depth and length cycloid site. According to Sonne, Ɛ = 2.

h - Depth of processing

bH - Width of the working body.

S - Submission on the

blade.

The disadvantage is eliminated by using a T-shaped

blade having a right -hand and left folds on one leg , for whom the square cut:

F = Fleg +Fshear=h(S+2

δ bH)

Scheme of formation of soil chips

Consequently , the surface cutting and thus the energy

consumption will be reduced by reducing

the area of the shear of blade leg .

Taking the ratio of expressions using the formulas (I) and (2) and

preformed it, we obtain :

Analyzing this relationship , we can conclude that cutting surface , and hence the energy

intensity of the milling process can be reduced by increasing the permissible

limits agricultural needs by ratio S/ bH and by reducing the area of

the shear of blade leg , which is confirmed by experimental

studies . Thus, data of

comparative tests show a reduction of

specific energy consumption milling soil I, I - !, 2 times experimental working

bodies compared with serial.