UDC

541.124.2

N.R. BUKEIKHANOV2, P.B. VOROBYEV1, I.M. CHMIR’2, L.V. LI1,

A.S. ZULKASHEVA1,

T.P. MIKHAILOVSKAYA1

1JSC «Institute of chemical sciences named after

A.B. Bekturov», Almaty

2FSBEI HPE Moscow State Technological University

“STANKIN”,

Russian Federation, Moscow

CONJUGATED AND COMBINED CHEMICAL PROCESSES

Abstract. Ñombined chemical

reactions include such leading industrial processes as oxidative chlorination,

oxidative ammonolysis, oxidative esterification whereby modern bulk products -

vinyl chloride, acrylonitrile, and terephthalo- and isophthalonitrile,

vinyl acetate are produced. Such well-known polymeric materials as polyvinyl

chloride (manufacture of double-glazing windows, linoleum, packaging

materials), polyacrylonitrile (manufacture of "nitrone" fiber, carbon

fiber-reinforced plastic), polyesters, polyamides, polyurethanes (synthetic

fibers, rubbers, adhesives), polyvinyl acetate (PVA building adhesive, the starting

material for the polyvinyl alcohol used to prepare the high modulus fibers and

others) are obtained from these monomers. A number of processes based on the

coupled reactions such as oxidative ammonolysis, oxidative dealkylation, producing

of terephthalic acid by liquid phase oxidation of p-xylene have been developed in

Kazakhstan under the supervision of academician of NAS RK - B.V. Suvorov.

Academician Boris Viktorovich Suvorov defined a

coupling as a key step of the complex reactions’ mechanism [1-3]. Consistently [4,

5], acceleration (and deceleration) reactions by combining two or more

components in a reaction mixture are typical for the conjugated complex

reaction mechanism. Suvorov and co-workers [6] proposed a methodological

procedure of defining conjugation stages in complex catalytic process, which lies

in a proof of the transfer of starting material fragments from one direction of

chemical process to another parallel direction by identifying the corresponding

reaction products. Thus, the transfer of fragments was detected by using heteroatomic

compounds as starting materials. For example, cyanopyridines are formed in small amounts in the process

of oxidation of methylpyridine (picoline) on the vanadium oxide catalysts,

along with the products of partial oxidation - pyridine carboxylic acid and pyridine

aldehyde. The efficiency of donor nitrogen (nitrogen-containing fragments) transfer

was determined by calculation of the experimental data of catalytic oxidation

of alkylpyridines by equation S = (A * 100) / [100 - (B + C)] where: S – selectivity

of nitrile formation, in%, A - nitrile

yield, in %, from the theoretically possible, B - the amount of unreacted

starting material, C - total yield of the defined reaction products, in%, from the

theoretically possible. According to calculations the selectivity of cyanopyridine

formation can reach 81% in the process of 2-methylpyridine oxidation [6].

Studying kinetics of heterogeneous catalytic

oxidation of 4-methylpyridine into isonicotinic acid, the raw material for

antituberculous drugs, it was able to detect the presence of coupling between

the stages of pyridine-4-aldehyde formation and deep oxidation of raw and desired

reaction product, carrying with nitrogen-containing fragments, which play a

role of the nitrogen donor for cyano

group formation [7]. The kinetic model of this reaction, carrying in the flow

integral reactor, represents a system of ordinary differential equations,

numerical solution of which was performed by the Gear method [8]:

-dC4-Pic/dt = (k1

+ k4 ) · C4-Pic;

dC4-PyCHO /dt = k1 · C4-Pic - (k2 + k6) · C4-PyCHO;

dC4-PyCOOH /dt = k2

· C4-PyCHO - (k3 + k5) · C4-PyCOOH ;

dCPy /dt = k3 ·

C4-PyCOOH;

dCCO2 /dt = k4

· C4-Pic + k5 · C4-PyCOOH;

dC4-PyCN /dt = k6 ·

C4-PyCHO.

The optimum values of kinetic stages’

constants were defined from the conditions of minimizing the sum of squared

deviations between experimental and calculated reagents’ concentrations by

using Powell’s method [9]. The standard deviation for each product does not

exceed 8%. Table 1 shows the calculated kinetic stages’ constants (kj) of

4-picoline oxidation over the V-Ti-Zr-oxide catalyst at the temperature of 245îÑ and different ways

of water supply into the contact area. The observed increase of the kinetic

stages’ constants of initial 4-picoline and intermediate isonicotinic aldehyde conversion

on increasing concentration of water vapor in the reaction mixture, presumably,

is connected with the increase in the surface catalyst acidity and enhancement

of its adsorption ability with respect to pyridine derivatives. It is known

that Bronsted acidic sites are formed as a result of the dissociative

adsorption of water molecules on the surface of oxide catalysts [10].

Table 1 - Influence of water

vapor concentration in the contact area on the kinetic stages’ constants of

4-picoline oxidation over the V-Ti-Zr-oxide catalyst at a temperature of 245îÑ. The initial

concentrations: [4-picoline] = 1,1·10-4,

[O2] = 9,4·10-3 mol·L-1.

|

Stages

|

|

kj , ñ-1 |

|||||

|

Mechanism

stages |

[H2O] ·103, mol·L-1 |

||||||

|

|

0 |

1,3 |

2,45 |

5,1 |

8,9 |

15,2 |

|

|

1 |

4-Pic ® 4-PyCHO |

1,788 |

1,970 |

2,799 |

3,891 |

4,269 |

4,241 |

|

2 |

4-PyCHO ® 4-PyCOOH |

1,713 |

1,968 |

3,790 |

6,249 |

6,389 |

9,571 |

|

3 |

4-PyCOOH ® Py |

0,290 |

0,126 |

0,080 |

0,088 |

0,078 |

0,056 |

|

4 |

4-Pic ® CO2 + NOx |

0,084 |

0,276 |

0,485 |

0,316 |

0,118 |

0,161 |

|

5 |

4-PyCOOH®CO2+ NOx |

0 |

0 |

0 |

0,667 |

0,434 |

0,514 |

|

6 |

4-PyCHO ® 4-PyCN |

0,164 |

0,597 |

0,814 |

1,079 |

0,862 |

0,650 |

According to calculations, the isonicotinic

acid is composed from 4-picoline through the stage of isonicotinic aldehyde formation

and partially decarboxylated at the stage ¹ 3 with pyridine formation. The

presence of 4-cyanopyridine in catalyzates’ experiments indicates that

generated nitrogen-containing fragments at the stage of deep oxidation of initial

4-picoline (stage ¹ 4) and isonicotinic acid (stage ¹ 5) play the role of a nitrogen

donor in relation to aldehyde at the stage ¹ 6 [11].

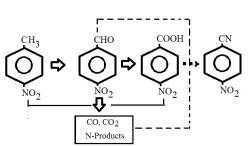

Experiments for p-nitrotoluene and 3-cyanotoluene

oxidation over V-Ti-catalyst showed that p-nitrobenzonitrile and

isophthalodinitril are formed along with the p-nitrobenzoic acid and m-cyanobenzoic

acid, the formation selectivity of which was 4-10 % per taken starting material

[12]. According to the process scheme (Figure 1), the starting and intermediate

materials are converted towards partial oxidation with aldehydes’ and acids’

formation and towards destructive oxidation, furnishing nitrogen-containing

fragments (potential nitrogen donors) and carbon oxides. Nitrogen donor transfer

from one reaction direction to another in coordination with n-nitrobenaldehyde

and p-nitrobenzoic acid leads to the formation of p-nitrobenzonitrile, which is

an absolute proof of the conjugated process nature. However, the examples of

obvious conjugation are likely special cases. In general terms, conjugation is

more widespread, but usually in an implicit form.

A number of processes based on the coupled

reactions such as oxidative ammonolysis, oxidative dealkylation, obtaining of

terephthalic acid by liquid phase oxidation of p-xylene have been developed in

Kazakhstan under the supervision of academician of NAS RK - B.V. Suvorov.

A number of processes based on the coupled

reactions [13], such as continuous method of producing terephthalic acid by

liquid phase oxidation of p-xylene; process of producing propylene by conjugated

liquid phase oxidation of propylene together with acetaldehyde [14]; conjugated

reactions of hexamethylene dehydrogenation and toluene or o-xylene hydrodealkylation

on palladium membranes [15] have been developed and proposed by B.V. Suvorov

and co-workers.

Fig.1. The p-nitrotoluene oxidation process scheme

over V-Ti-catalyst

One of the methods of chemical processes’

formation lies in ammonia substitution in the reaction of catalytical oxidative

ammonolysis for another nitrogen donor and air substitution for another

oxidant. Thus, the process of producing benzonitrile by toluene and ammonia

oxidation of sulfur dioxide on aluminum oxide and other catalysts (the yield of

nitrile is 62%, the selectivity is 92%)

was developed, and called similarly with oxidative ammonolysis

«ammonsulfooxidaton» [16].

The ammonolysis processes have been implemented

into industry for the purpose of producing benzonitrile from toluene, phthalodinitril

from o-xylene, nicotinonitrile from β-picoline, wherein

the movable catalyst oxygen was an oxidizing agent, the reduced form of which was

activated by air in the auxiliary reactor [17]. The process of

«nitrooxydation», wherein benzonitrile is synthesized from Te, Fe, Pb, Sn oxides on the catalyst, with the yield of 67%

by reacting 1 mole of toluene with 2 moles of NO, have been investigested. The

latter acts both as oxidant, and nitrogen donor [18].

Based on analysis of literature data array on

catalytic oxidation reactions we made a conclusion that it is possible to

isolate group reactions, which on its phenomenological characteristics approach

to the reaction of oxidative ammonolysis mentioned above. They all take place

by a single scheme: the starting material + coreactant + oxidizing agent + catalyst

→ reaction product (usually not containing oxidizing agent in its

compound). Examples of such reactions are shown in Table 2. A lot of them have analogues

carried out in the liquid phase, for example, the catalytic and non-catalytic

oxidative ammonolysis [11], oxidative chlorination, oxidative etherification [11].

Of course, such different reactions do not

proceed by the same mechanism. However, common phenomenological characteristics

(performing reactions in the presence of oxidizing agents and as a rule,

semiconductor catalysts, dependence of speed and processes’ selectivity on

additions of various substances in the starting reaction mixture, producing the

desired product which does not have oxidizing agents in its compound) were used

as a reason to define the generality in the regularities of these processes

[11, 19, 20].

Table 2 - Complex

gas-phase oxidation processes.

|

Starting

materials |

Catalyst, temperature |

Basic

process product |

References |

|

|

1.

Oxidative alkylation |

||||

|

Benzene, ethylene, Î2 |

Pt, 2000C |

Styrole Ñ6Í5ÑÍ=ÑÍ2 |

11, p. 97 |

|

|

Benzene, methane, Î2 |

FeOX,TiOX, 6000C |

Ethylbenzene + Styrole |

||

|

2.Oxidative

hydroxylation |

||||

|

Benzene methanol, Î2 |

Silica, Â2Î3,

6400C |

Phenol |

22 |

|

|

3.

Oxidative chlorination |

||||

|

Ethylene, 2HCI, 0,5 Î2 |

CuCl2 ,2000C |

Dichloroethane |

11, ch.8 |

|

|

Benzene, HCI, 0,5 Î2 |

Cu, Fe chlorides, 2150C |

|||

|

4.

Oxidative

etherification |

||||

|

Ethylene, ÑH3COOH, Î2 |

PdCl2 , 160-2000C |

Vinyl acetate CH2=ÑÍ-OÑO-CH3 |

11,ch.5 |

|

|

Ñ6Í5ÑOOÍ, ÑÍ3OÍ, Î2 |

VXOY |

Ñ6Í5ÑOOCH3 |

||

|

5.

Oxidative cyanation |

||||

|

Methane, acetonitrile,

Î2 |

Silica,

6000C |

CH3ÑÍ2ÑN + CH2=ÑÍÑN |

11, ch.4 |

|

|

Styrole, HCN, Î2 |

PdCl2, KCl, 2500C |

Ñ6Í5ÑÍ=ÑÍCN |

||

|

6.

Oxidative heterocyclization |

||||

|

CH2=ÑÍÑÍÎ, NH3, Î2 |

Cu, Zn, Pb, Ag oxides, 350-4000C |

Pyridine, 3-methylpyridine (β-picoline) |

11, p. 99 |

|

|

7.

Oxidative ammonolysis |

||||

|

CH2=ÑÍÑN, NH3, Î2 |

Bi, Mo oxides, 250-4500C |

CH2=ÑÍÑN, acrylonitrile |

11, ch. 6, 23 |

|

|

Substituted alkylbenzenes (substitutes – haloids, oxy-, alkoxy-, nitro

group), NH3 , Î2 |

V,Ti, Mo, B, P oxides, 350-4000C |

Benzonitrile, di-, tri-cyanbenzenes and corresponding derivatives with

haloids, oxy-, alkoxy-, nitro groups |

||

|

Pyridine, 2-, 3- è 4- methylpyridines |

V,Ti, Mo, Bi oxides, 350-4000C |

2-, 3-, 4- cyanpyridines |

||

|

8.

Ammonsulfooxidation |

||||

|

Toluene, NH3 ,SÎ2 |

Al, Si, Zr, V oxides, 4000C |

Benzonitrile |

11, p. 136 |

|

|

9.

«Lammas»-process |

||||

|

Substituted alkylbenzenes,

NH3 |

V superoxides, 4000C |

Benzonitrile and

corresponding derivatives |

11, p. 132,155-157 |

|

|

10. Oxidative nitrilling |

||||

|

Toluene, HCN or CH3CN, Î2 |

Cu,V,Ti

oxides, 400-4500C |

Benzonitrile |

11, p. 110, 422 |

|

|

Toluene, nitrobenzene or aniline, Î2 |

V,Ti

oxides, 400-6000C |

|||

It can be concluded that a

significant number of complex reactions mentioned above are genetically connected

with heterogeneous oxidation reactions conducted in various extreme conditions.

Also reactions, in which the main direction of the process is caused by

non-oxidative conversions, can be associated, for example, the reaction of

oxidative etherification. However, here too

the oxidizing agent is required for the total process. In most considered

reactions the catalyst operates according to reductive-oxidative mechanism, where

the oxidizing agent performs the function of reoxidation of reductive active

catalyst sites by organic matter and co-reactant. The conjugated process

character have been proven for a number of processes such as oxidative

ammonolysis, ammonsulfooxidation, conjugated oxidative dehydrogenation,

oxidative chlorination [11]. However, the conjugation role is still an open

question, therefore, all processes shown in the table should be primarily

attributed to a complex combined processes including stages of different

consecutive, parallel and coupled reactions.

The method of chemical

processes’ formation by introducing an oxidizing agent into a mixture of basic

co-reactants, the components of which are part of the desired product, was

quite productive. It allowed to create such leading industrial processes as

oxidative chlorination, oxidative ammonolysis, oxidative etherification, according to which modern bulk

products - vinyl chloride, acrylonitrile and vinyl acetate have been produced

[21]. Such well-known polymeric materials as polyvinyl chloride (manufacture of

double-glazing windows, linoleum, packaging materials), polyacrylonitrile

(manufacture of "nitrone" fiber, carbon fiber-reinforced plastic),

polyvinyl acetate (PVA building adhesive, the starting material for the

polyvinyl alcohol used to prepare the high modulus fibers and others) are

obtained from these monomers. Other examples of complex reactions are given in works

[22, 23].

REFERENCES

1. B.V. Suvorov, S.R. Rafikov, A.D. Kagarlitskiy. The oxidative

ammonolysis of organic compounds // Usp. - 1965. - T.35, ¹9. - p. 1526-1549;

2. B.V. Suvorov. The oxidative ammonolysis of organic compounds. -

Almaty, Science of the Kazakh SSR, 1971. – p. 146;

3. B.V. Suvorov in the book; V.A. Volkov, E.V. Vonskiy, G.I. Kuznetsova.

Outstanding chemists of the world. Edited by G.I. Kuznetsova - M.: High School,

1991. – p. 656;

4. N.N. Shilov. Conjugate oxidation reactions. - M., 1905. - p.304;

5. N.M. Emanuel, D.G. Knorre. Course of chemical kinetics, 4th ed. - M.,

High School, 1984. - p. 463;

6. N.R. Bukeikhanov, B.V. Suvorov, B.T. Dzhusupov and others. The

conjugated character of contact oxidation of some nitrogen-containing organic

compounds // Math. Academy of Sciences of the Kazakh SSR, Ser. chem. - 1977,

¹3. - p.48-52;

7. P.B. Vorobyev, T.P. Mikhailovskaya, R. Kurmakyzy, A.B. Dikhanbayev, D.H.

Sembaev. Partial oxidation of 4-picoline on V2O5 and

promoted vanadium oxide catalysts // Chem. Journal. of Kazakhstan. - 2010, ¹ 4.

- p. 58-66;

8. L.S. Polak, M.J. Goldenberg, A.A. Levitskyi. Computational methods in

chemical kinetics. - M., 1984. - p. 280;

9. D. Himmelblau. Experimental nonlinear programming. - M., 1975. - p.536;

10. V.F. Kiselev, O.V. Krylov. Electronic effects in adsorption and

catalysis on semiconductors and dielectrics. - M., 1979. - p.236;

11. B.V. Suvorov, N.R. Bukeikhanov. Oxidation reactions in organic

synthesis. - M. Chemistry, 1978. - p.197;

12. B.T. Dzhusupov, N.R. Bukeikhanov, B.V. Suvorov. Synthesis of

aromatic nitriles by oxidation of alkylbenzenes with organic nitrogen-containing

compounds // Math. Academy of Sciences of the Kazakh SSR, Ser. chem. - 1977, ¹

4. - p. 66-70;

13. L.G. Manukovskaya, A.V. Solomin, B.V. Suvorov, S.R. Rafikov.

Continuous method of producing terephthalic acid by liquid phase oxidation of

p-xylene // Petrochemistry. - 1962. - B. 2, ¹4. - p. 531-535;

14. N.M. Emanuel, O.N. Dyment, E.A. Blumberg. Modern methods of ethylene

oxide and propylene oxide production // Journal. WMO named after D.I.

Mendeleev. - 1969. - B.14, ¹3. - p. 238-262;

15. V.M. Gryaznov. Reaction conjugation by using membrane catalysts // Kinetics

and catalysis. -1971. - B.12, issue 3. - p. 640-645;

16. H. Hoffmann. Ammonsulfooxidation

// Chem. Zeit., Chem.Apparat. - 1967, ¹12. - P. 392-398;

17. J.E. Paustian,

F. Pustio, N. Stavropouls, M. Sce. A lesson inflow sheet design nicotinamide

and acid // Chem.Techn. –1981. – V.11, ¹ 3. – p. 174-178;

18. E. Fisher.

Preparation of aromatic nitriles by means of a new vapor phase reaction //

Chem.Ind.Techn. – 1966. – Bd.38. – p. 35-37;

19. V.S. Zulkasheva, N.R. Bukeikhanov, B.V. Suvorov. The oxidative

ammonolysis of mixtures of some methylbenzenes // Iss. Academy of Sciences of

the Kazakh SSR, Ser. chem. - 1980, ¹5. – p. 48-51;

20. B.V. Suvorov, N.R. Bukeikhanov, L.V. Li. Ways of processes intensification

of nitriles production on the basis of oxidative ammonolysis reaction of

organic substances // In book.: Synthesis and study of monomers and polymers. -

Alma-Ata, Science. - 1983. - p. 3-23;

21. L. Berdick Donald, William L. Leffler Petrochemistry/ trans. from

English. - M .: CJSC "Olymp-Business." - 2001. - p. 416;

22. D.R. Ashmead Brit. Pat. ¹

1274653, 1972. Oxydation of Hydrocarbons.

23. N.R. Bukeikhanov, B.V. Suvorov. Synthesis of substituted aromatic

nitriles. - In coll.: Chemistry of monomers and polymers. - Alma-Ata, Science,

1980. - p. 3-15.